Posts Tagged acoustical materials

Demystifying Acoustic Data: Part 1 – Absorption vs Isolation

Posted by Acoustics First in Absorption, Articles, Product Applications, Products, Sound proofing, Video on August 16, 2016

For anyone new to the world of acoustics, there is a multitude of terms, coefficients and numbers that are thrown around. This flood of information can seem intimidating, especially to beginners. In this series, acoustician Cameron Girard of Acoustics First® hopes to help you distinguish between what’s useful and what’s not.

Part 1: Acoustic Terminology – Sound Absorption vs Sound Isolation

In order to make informed decisions about acoustical treatment, it is vital to know the difference between materials that are meant to absorb sound within a room and materials that are meant to block sound from leaving or entering it. In an overly reverberant auditorium, absorptive treatment is needed to reduce echoes and improve speech intelligibility. If the problem is sound passing in between spaces, like offices or apartments, then isolation treatment is required. These are two separate acoustic issues which require separate solutions.

In both scenarios, it is important to know which data is relevant and helpful. Also, given sheer volume of information available on the internet, it is perhaps unavoidable that some info will be incomplete or simply incorrect. It should not be assumed that something which sounds technical is, in fact, backed up by proper testing.

Terms for Sound Absorption

We recently encountered an acoustical ceiling tile which was said to “absorb 50% of sound”. On the surface this sounds like an extremely efficient product. However, let’s delve in closer and decipher what is actually usable information, and what is just marketing.

When sound waves meet a room surface such as a wall, ceiling or floor, some of the sound energy is reflected back into the room and the rest is considered to be “absorbed”. The absorbed sound energy has not vanished, it’s actually been converted into kinetic (vibration of a solid material) and thermal energy (heat due to friction within a porous material) or has simply passed right through the material (transmission). The more surface area a certain material has the better absorber it will likely be. “Soft” materials, like heavy blankets, fabric and fiberglass, have loads of nooks and crannies, which sound tries to “fill”. These porous materials are great for reducing reverberation within a room, but will only marginally reduce the sound that leaves it (but more on that later).

Sonora® wall and ceiling panels are used for absorbing sound within a space.

When comparing sound absorbing products, there is a particular set of terms you should look for: The Sound Absorption Coefficient (SAC) and Noise Reduction Coefficient (NRC). These are used to specify the fraction of incident sound that a material absorbs per 1’x1’ area. An NRC of 1.0 indicates perfect absorption (an open 1’x1’ window) and a value of 0.0 represents perfect reflection (polished concrete has an NRC of .02).

To measure sound absorption, a large sample of the material is placed in a reverberation room with all other surfaces being hard and reflective. The time it takes a test sound signal to decay by 60dB (rough point of inaudibility) after the source of sound is stopped is measured first with the sample in the room and again with the room empty. The difference in decay time defines the efficiency of the absorbing material and thus the absorption coefficients. Large spaces with low-NRC materials (tile, drywall, etc.) have longer reverberation times, while small rooms furnished with high-NRC materials sound much more “dead”.

Clearly, a single 2’x2’ ceiling tile is not going to reduce the reverberation in a real-world space by 50%. So is the above claim false? Not exactly… The ceiling panels do have an NRC rating of .50, so the tile does absorb 50% of incident sound. However, one might assume a much more drastic improvement based on the “50%” claim. In reality you’d need a large square footage of these ceiling tiles to cut the amount of total reflected sound in half. Always be sure to check the NRC number!

Terms for Sound Isolation

Our customers often call with issues related to neighbor noise or office-to-office privacy and are looking for “sound proofing” treatment. Unfortunately, many do not realize that simply installing acoustic foam or fiberglass panels will not appreciably reduce the level noise entering and leaving their space. These absorptive materials are great at reducing unwanted reflections within a room because they are porous and air/sound energy can flow through them. That being said, they are generally poor sound barriers for this exact reason. They will help to reduce noise buildup in a room and improve the ‘acoustics’, but will do very little to “block” sound coming in or out.

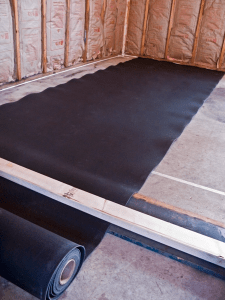

BlockAid® is a heavy, impermeable barrier for stopping the transmission of sound.

Sound is like water; it will “flow” into an adjacent space if everything isn’t sealed up. Materials that are air tight and heavy, like our BlockAid® sound barrier, provide the most relief of air-born sound transmission. Continuous coverage of floors/ceilings or walls is necessary to ensure that sound doesn’t ‘flank’ around these barriers. Multiple layers of varying materials, the use of resilient clips or channels, and additional walls will provide even more control. For a demonstration of how different materials affect sound isolation, check out our video http://acousticsfirst.com/educational-videos-the-barrier-and-the-bell.htm

Like NRC for sound absorption, there is also a laboratory tested figure that can be used to compare the sound “blocking” properties of acoustic barriers and wall constructions: Transmission Loss (TL) and Sound Transmission Class (STC). These describe how much air-born sound is attenuated through a given material.

In the lab, the material to be tested is mounted over an opening between two completely separated rooms, one with a speaker (source) and the other with a microphone (receiver). Save for the open “window”, these rooms are completely isolated with thick and massive walls, so virtually all the sound energy transmitted between rooms will be through the test specimen. The difference between sound levels in the source room and the receiving room is the transmission loss (TL). The TL is measured at multiple frequencies, which is fitted to a Sound Transmission Class (STC) “curve” at speech frequencies (125Hz-4kHz). The STC of the material is the TL value of the fitted curve at 500 Hz. For example, a material with an STC of 27 typically “blocks” 27dB of sound. Keep in mind though, the STC’s of materials do not add up linearly; in other words, adding a material with an STC of 27 to an existing wall with an STC 45 will not result in an STC of 72.

As always, Acoustics First is here answer questions and help you find the best solutions.

Sound Channels® – Top Product!

Posted by Acoustics First in Absorption, Classrooms, Customer Feedback, Mentions, Press Release, School & Educational Facilities on December 22, 2015

Acoustics First® Sound Channels® wall fabric has been named a ‘2015 Top Product’ by Christian School Products magazine!

http://www.cspmagdigital.com/publication/?i=284531&p=18

Christian School Products – 2015 Top Products

This article from their November issue explains why:

Merry Christmas and Happy New Year from all of us at Acoustics First!

D is for Dean’s List!

Posted by Acoustics First in Company Information, Diffusion, School & Educational Facilities on September 18, 2014

We are proud to announce that the Art Diffusor® Model D has been awarded the PUPN Dean’s List Gold Award for 2014!

While the Model D is one of our newest diffuser designs, it is also one of our most recognizable products and has heard the praises sung from video and audio recording and broadcast studios, editing and mastering suites, theaters and listening rooms, music rooms and practice spaces, schools and even acoustic testing labs!

Click Here or the Logo to see the actual award page.

Pick up some Model D’s for yourself.

Check out the award winning Model D’s and our other award winning products at

www.acousticsfirst.com

DIY: Back Wall Diffuser Array/Bass Trap

Posted by Acoustics First in Absorption, Auditorium, Broadcast Facilities, Diffusion, DIY, Home Entertainment, Home Theater, HOW TO, Media Room, Multipurpose Rooms, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Products, Recording Facilities, Recording Studio, Restaurants, Studio Control Room, Teleconferencing, Theater, Vocal Booth, Voice Over, Worship Facilities on June 20, 2013

Getting more out of your back wall diffuser array with a simple hanging DIY array/bass trap.

One of the big “back wall” questions people have is “If I have a large diffuser array, how can I get the bass trapping I need?” A great answer to this question is to turn the entire array into a hanging bass absorber. If you are already planning on getting diffusion for your back wall, here is a great way to use that wall space for more than just diffusion.

Stuff you need:

- 4’x 8’ sheet of 3/4” Plywood

- 32 sq/ft of 4” Cutting Wedge® Classic Foam (Or similar absorber)

- 8 x Art Diffusers® – Model C (or Model F, Quadrapyramid™, or other comparable diffuser)

- 2 x IsoHangers

- 2 x Heavy rings (Think big Curtain Rings or Hanging Wire will also work)

- 2x Closet Rod/Shelf Brackets

- 2 x 7/8” wood screws and fender washers

- Construction Adhesive (Make sure it’s safe for Foam)

Assembly instructions

- Screw the two IsoHangers to the plywood, using a fender washer on each screw. These should be about an inch in from each end -drill small pilot holes first. (These will be used to hang the panel, this side will be designated as the back from here on out.)

- Use Construction adhesive to attach the Cutting Wedge® Foam to the back of the panel in a checkerboard pattern (each panel 90° rotated from adjacent)

- Use Construction adhesive again to attach the 8 Diffusers to the front of the Plywood (Follow the installation instructions for adhesive placement)

- Attach the Rings or Wire to the free end of the IsoHangers.

What you have created is a hanging panel that will diffuse mid-high frequencies and trap the lows. The hanging mass absorbs low frequency energy by moving slightly when pushed by the energy of the Low frequency Waves. The rear facing fiberglass also absorbs low frequencies by dampening the panel, but it also absorbs any of the waves that happen to get trapped behind the panel.

Hanging the Diffuser/Trap Assembly

- Measure and attach the Closet Brackets to the Wall – Use appropriate anchors! If you have standard or double wall construction without Resilient Channels, use the studs – The IsoHangers will keep vibrations from transmitting through the wall.

- Hang the panel on the Closet Brackets using the rings/wire with the Diffusers facing you and that’s it!

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. For those customers who are planning on purchasing diffusers to make an array, or maybe already have an array and are looking to try a new configuration – this project may be what you’re looking for.

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. For those customers who are planning on purchasing diffusers to make an array, or maybe already have an array and are looking to try a new configuration – this project may be what you’re looking for.

A little History…

If you embark on this little construction project, you will be constructing studio elements that have remained basically unchanged since at least the early 1970’s. Hanging plywood wrapped in studio foam or fiberglass has been used “behind the curtains” of many of the top studios for effective bass control for over 40 years – just no one has ever seen it, as it has been hidden in walls; masked as a false wall of fabric stretched across wooden louvers!

————————————————————————————————————————————————————————————

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

You must be logged in to post a comment.