Archive for category HOW TO

John Bullard Live Room – Tuning a Live Room for Classical Banjo

Posted by Acoustics First in Absorption, Customer Feedback, Diffusion, HOW TO, Music Tracking Room, Product Applications, Products, Recording Facilities on May 3, 2023

When you think of classical music; what instruments come to mind? Piano? Violin? Cello? …What about Banjo?

In the summer of 2022, classical banjoist John Bullard reached out to Acoustics First for assistance with his newly renovated home-studio. John is one of a select group of classical musicians aiming to showcase the versatility of this uniquely American instrument. The banjo, with John’s expertise, lends a very distinct, melancholy sound to contemporary and traditional compositions.

Having recorded a number of albums already, John knew he wanted his live room to be catered specifically to tracking solo, classical banjo as well as small acoustic ensembles. Acoustics First analyzed John’s live room and came up with a treatment design that would achieve an “ideal-as-possible” acoustic environment for recording classical instruments.

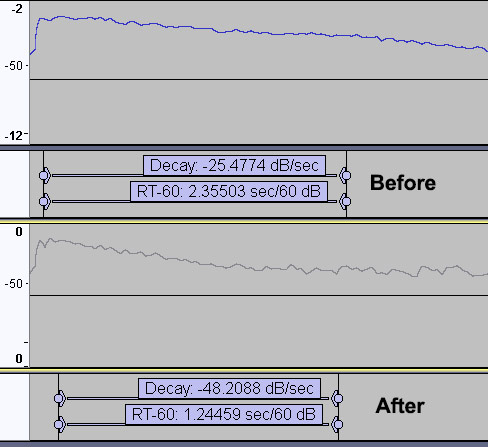

The largely reflective live room had walls comprised of unfinished, reclaimed wood planks over plywood, a drywall ceiling, stone fireplace and a polished concrete floor. The parallel, hard surfaces contributed to a poor tracking environment; with standing waves and “flutter” echoes adding unwanted coloration to recordings, inhibiting music definition.

Spaces used for rehearsing and recording classical music often benefit from elevated levels of reverberation, which add a sense of warmth and ambience to acoustic music. Although the reverb in John’s untreated room was only slightly excessive when measured, it was far from “diffuse”, with the majority of energy coming from early reflections.

The primary challenge in the live room was to address the early specular reflections and standing waves without taking too much “life” out of the room. To achieve this delicate balance, wide band diffusion was recommended as the primary ceiling and wall treatment with selective sound absorptive treatment with fabric-wrapped Sonora® panels.

Double Duty Diffusers™ and Aeolian® sound diffusers were recommended as they would also provide some much needed low-frequency absorption in addition to broadband diffusion.

After the treatments were installed, John got right to work on experimenting…

“…ready to start doing extensive test recordings to locate the best spot and rug configuration for solo banjo… It sounds really good to my ear – now to see how the microphones hear it!”

John Bullard

Please check out John Bullard’s music!! – https://www.johnbullard.com/

Ken Fritz – 1942-2022

Posted by Acoustics First in DIY, Home Entertainment, Home Theater, HOW TO, Media Room, Mentions, Uncategorized on August 18, 2022

Back in April 2021, Acoustics First® Posted a blog about a listening room designed and built by Ken Fritz. This is an overly-simplified statement, as he not only designed and built the structure, but also the massive speakers, the high-tech turntable, and many of the other components. The next month, John Gardner, Nick Colleran, and Jim DeGrandis were invited to witness Ken’s masterpiece of a room in person – and now, a year later, Ken is no longer with us.

Let’s back up a little bit. The history of this room goes back decades, and there is a common history between this room and the Acoustics First® HiPer Panel®. While Ken was finishing the structure back in the early 2000’s, he was focused on building a room that would help his speakers reach their ultimate potential. He had researched the geometry of the finest halls and theaters and their construction, but he was looking to take it one step further. When he was shopping for acoustic treatments for the space, he came across Acoustics First® – which was near his home. At the time, Nick Colleran and John Gardner were working on ideas for a new type of multi-layer, perforated composite, which would eventually become the HiPer Panel®. After the product completed development, and its patent was still pending, Ken’s room became the first installation of the new product.

Ken consulted with Nick and John multiple times during the long construction process, his uncompromising attitude toward his space was always looking for the “best way, no matter what it took.” His bass traps were styled after professional mastering facilities, where the entire corner was recessed and filled with low-frequency absorption. His ceiling was modeled to direct the reflections toward the upper rear of the room, above the balcony. The speakers were hand built, as was his turntable – all of which were marvels of engineering and detail.

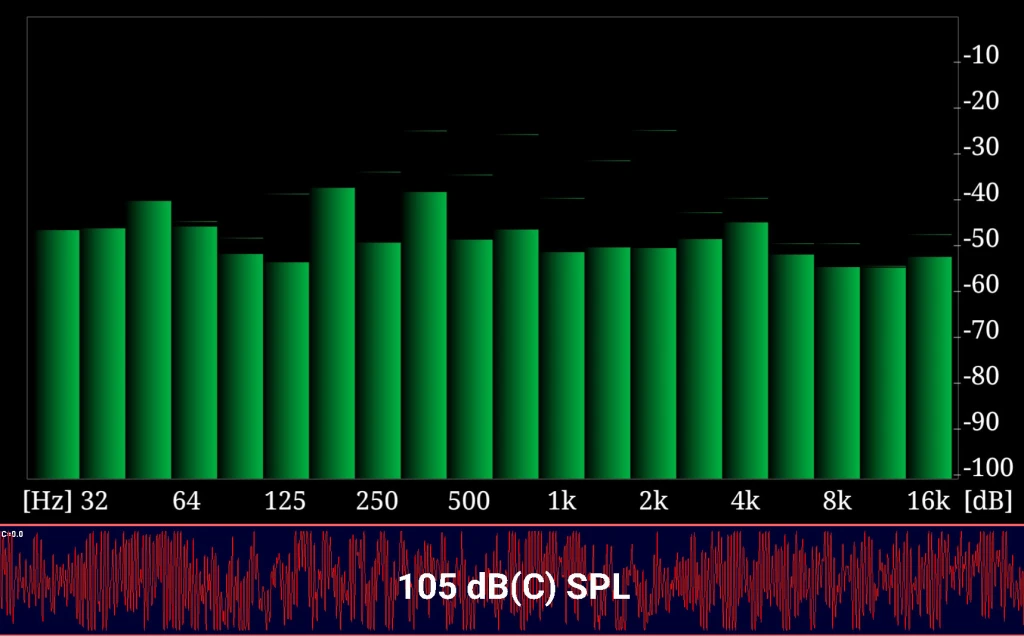

I will never forget Ken’s enthusiasm when he indulged in listening to his favorite recording of the “1812 Overture”, complete with Howitzer cannons. The magnitude of the sound would have shaken everything in the room, had Ken not meticulously isolated and anchored everything. The sound was pure and clean, even at 105dB (standing at the rear of the room – and balanced perfectly.)

But Ken wasn’t just about the music or the gear, he also liked to educate and learn. After listening to the recording, he went on to discuss how they had recorded the cannon shots, and even had an audio sample of the different “takes” done during the setup. This was Ken… he wasn’t just interested in how it sounded, but the process of how they got there.

We hope that Ken’s enthusiasm continues to inspire those who have an uncompromising love of music and sound, and that he will be remembered as one of the most fervent proponents of “following your dream.”

Thanks, Ken.

Absorption & Diffusion – The Construction Specifier

Posted by Acoustics First in Absorption, Art Galleries, Articles, Auditorium, Broadcast Facilities, Diffusion, Home Entertainment, Home Theater, HOW TO, Industrial Facilities, Media Room, Multipurpose Rooms, Music Rehearsal Spaces, Offices, Product Applications, Recording Facilities, Studio Control Room, Teleconferencing, Theater on April 29, 2022

For the May 2022 edition of “The Construction Specifier,” Acoustics First was asked to illustrate the use of absorption and diffusion in creating optimal acoustic spaces. The article is a great reference for understanding the types of acoustic absorbers and diffusers, as well as some use scenarios like offices, critical listening spaces, and larger communal spaces.

Note: This version has been edited and the advertisements are removed. The full published version of the May 2022 digital edition can be found on The Construction Specifier’s website here.

Sonora® Wall Panels on the Ceiling?

Posted by Acoustics First in Absorption, HOW TO, Product Applications, Products, Restaurants on February 25, 2022

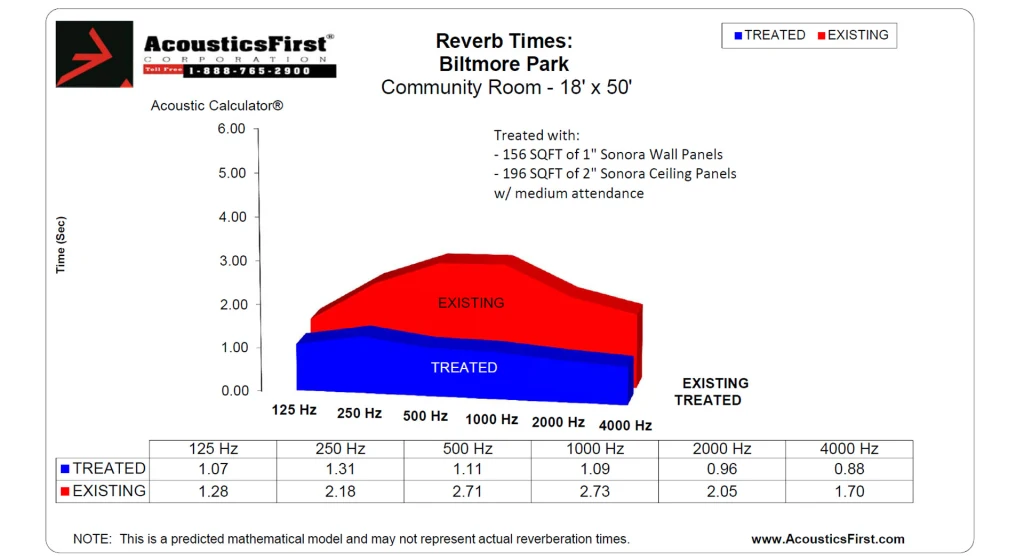

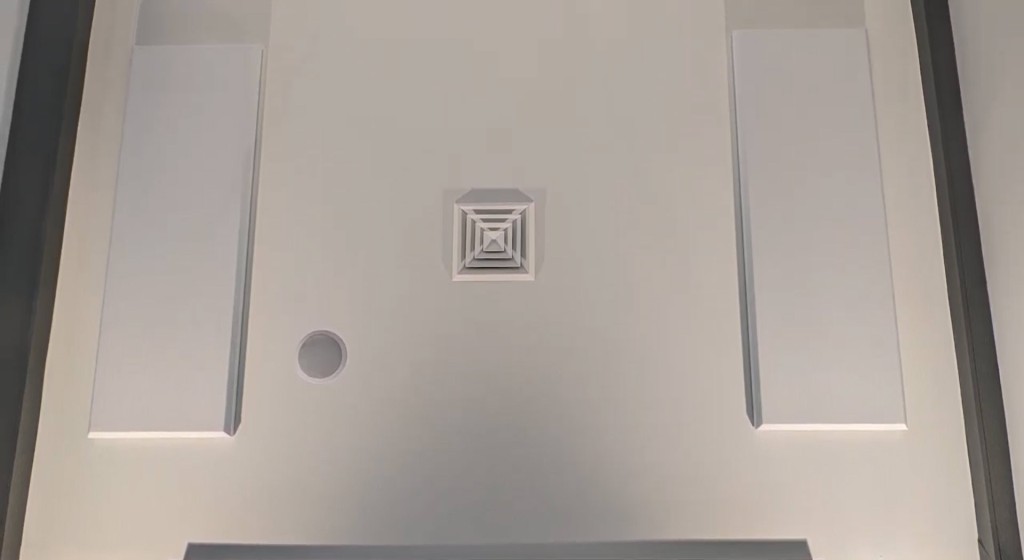

Sometimes you just don’t have the wall space for acoustic treatment. When this is the case, you will often see treatments move to the ceiling… but what do you do if you have lower ceilings, or many ceiling fans and fixtures?

This ceiling was sloped toward the massive windows on the outside wall, and it had lights and fans running right up the center. Complicating things further, the opposite wall had sconce lighting, doorways, HVAC, and even more windows. Finally, the floor was not carpeted to facilitate cleaning – as is the norm in many dining spaces.

Direct-mount acoustic panels are a great solution in these scenarios. Here we see an array of 4’x4’x2″ Sonora® panels attached to the ceiling in rows running down the length of the space. While our Tone Tiles® are often selected for their ability to blend in aesthetically, this particular installation proves that Sonora® panels wrapped in fabric are also a solid choice.

You must be logged in to post a comment.