Archive for category Voice Over

Sonora® LFC – Low-Frequency Control Panel

Posted by Acoustics First in Absorption, Auditorium, Home Entertainment, Home Theater, Multipurpose Rooms, Music Rehearsal Spaces, Music Tracking Room, Press Release, Product Applications, Products, Recording Facilities, Recording Studio, Studio Control Room, Theater, Uncategorized, Vocal Booth, Voice Over, Worship Facilities on May 24, 2021

Bass frequencies are difficult to control… and there is sometimes a tendency to overuse standard, broadband panels to try to absorb everything in order to get rid of that bass. However, this method is unbalanced and has the side-effect of leaving a room sounding muffled and boomy.

Why?

Physics! High frequencies are easier to absorb than low frequencies. So, when you ONLY use broadband absorbers, they easily remove the high frequencies and leave more of the lows. Overusing broadband absorption in a large performance space can be a disaster – leaving an environment lacking energy and feel – many describe this condition as a room sounding “dead.” (Not good!)

So how can you treat the boomy bass without killing your rooms with too much broadband absorption? Can you just take out the bass? Unfortunately, it is impossible to ONLY absorb the bass, but we can LIMIT the amount of high frequency energy that we absorb to balance out the response.

Acoustics First® presents… the Sonora® LFC – Low-Frequency control panel.

The Sonora® LFC looks like a standard Sonora® Wall panel, but looks can be deceiving! At 4-1/8″ thick, it is virtually indistinguishable from a High-Impact Sonora® panel – however the interior structure of the LFC is optimized to attack the bass frequencies and smoothly roll off the high frequencies. Let’s take a closer look at the performance difference between the Sonora® LFC and the standard Sonora® panel.

When you look at the performance charts, you will notice that the standard 4″ Sonora® panel starts to “roll-off” in the lower frequencies below 125 Hz – it still absorbs them, just to a lesser degree. We designed the Sonora® LFC panel to focus on those frequencies below 125 Hz – while allowing the other treatments to handle the rest! This allows you to use fewer broadband panels, and still have some high-frequency energy for diffusers to spread around – thus creating a more balanced acoustic environment.

The Sonora® LFC is an engineered solution using the same high-performance materials as our other products, but combining them in a way that optimizes them for Low-Frequency Control – hence Sonora® LFC! The magic is in the way those materials are used.

All of the materials used in an acoustic environment have a function – “Diffusers,” “Absorbers,” and “Bass Traps” are all general descriptors of product functions. Some diffusers are also Bass Traps. Some bass traps are also broadband absorbers. Some diffusers use absorption for amplitude grating. By combining a dampened, resonant trap with multi-density fiberglass, the Sonora® LFC focuses on making acoustic spaces more balanced. For controlling the bass without sucking the life out of a room, the LFC Panel is an outstanding tool for refined Low-Frequency Control!

ArtDiffusor® Model C and Model F – Similar, yet different.

Posted by Acoustics First in Diffusion, Media Room, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, Studio Control Room, Theater, Uncategorized, Vocal Booth, Voice Over on August 20, 2020

We often get asked about the functionality of the different diffusers, and one of the frequently asked questions is about the differences between the ArtDiffusor® Model C and ArtDiffusor® Model F. We will cover some of similarities and differences in the design, functionality and use of these two devices.

Design.

The Model C and Model F use identical math to come up with their basic structure, they even have angled faces – the main difference between the two is that the Model F elements are ½ of the Model C’s height, length and width – and then it is duplicated 4 times in the same footprint… The Model C is nominally 2’ x 2’ x 4” deep. The Model F is four quadrants that are nominally 1’ x 1’ x 2” deep – like little scaled down Model C’s… This makes them visually similar and aesthetically compatible. This low profile design makes the Model F more desirable for ceiling installs in spaces with very limited headroom – like basement studios that have low ceilings.

Performance

Due to the different size of the elements on the two devices, they have very different frequencies at which they are most effective. The Model C is a mid-frequency diffuser by design… having larger elements and deeper wells than the Model F. The Model F is primarily a high-frequency diffuser, due to the small elements and lower profile. Both diffusers are tuned to different frequencies as their “primary range,” and while they do affect lower and higher frequencies than they are designed for – it is to a lesser degree, or the product of absorption.

What does this mean?

The Model C has a primary design range of 1KHz to 4KHz. This is where it is primarily designed to work. It can and does diffuse below 1KHz and over 4KHz – just to a lesser degree than its primary design range.

The Model F has a primary design range of 2KHz to 8KHz, and again, it does diffuse outside of that range, but to a lesser degree.

The angled caps of both the Model C and Model F help to extend their high frequency range by reflecting sound in different directions at higher frequencies – causing the sound to scatter spatially. The different heights of the elements cause sound reflections to be offset “temporally,” or in time. The sound that hits the higher elements is reflected sooner than the sound that hits the lower elements – travelling further before it is reflected. This time offset, changes the “Phase Coherency” of the reflection; the larger the difference in the heights, the greater the offset in time.

The size of the elements matters as well. The shorter wavelengths of high frequencies can diffract and scatter off of the smaller elements of the Model F more readily than low frequencies, which see the Model F as a slightly angled & mostly flat surface. However, the lower frequencies are more affected by the larger and deeper elements of the Model C.

How do these differences help define their use?

The Model C is a great all around diffuser – it covers a wide range of frequencies, throws a very predictable 2D diffusion pattern, and it is tuned to a very musical range.

The Model F is a great high-frequency diffuser. It targets a few very specific, yet important issues. High frequencies are responsible for some nasty problems in rooms. Flutter echoes, ringing, comb filtering, and other artifacts are particularly noticeable in higher frequencies. If your room is otherwise performing well acoustically, the Model F can help tackle that last hurdle to make a good room into a great room.

Many critical listening environments use both the Model C and Model F to tune the diffusion in their space.

While the white Aeolians® on the back wall are the visual focal-point on in Big3 Studio A, look closely at the ceiling and you will notice a large array of black Model C’s and Model F’s. These help to intermix the diffusion of different frequencies in the large control room.

Due to their aesthetic and functional compatibility, many rooms benefit from using both. Model C’s addressing the bulk of the Mid-range diffusion, and the Model F smoothing out the top end.

I hope that this highlights the unique properties of both the ArtDiffusor® Model C & ArtDiffusor® Model F – and helps to demystify their function and use in your space.

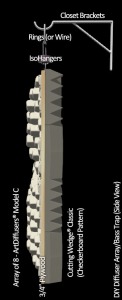

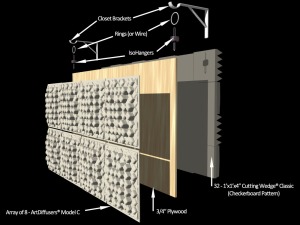

DIY – Back Wall Diffuser Array/Bass Trap: Revisited

Posted by Acoustics First in Absorption, Articles, Broadcast Facilities, Customer Feedback, Diffusion, DIY, Home Entertainment, Home Theater, HOW TO, Media Room, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, Studio Control Room, Teleconferencing, Theater, Vocal Booth, Voice Over on July 14, 2016

This month we thought we’d share a few Real-Life pictures of an idea we first introduced back in summer of 2013: The “Back Wall Diffuser Array/Bass Trap”.

This month we thought we’d share a few Real-Life pictures of an idea we first introduced back in summer of 2013: The “Back Wall Diffuser Array/Bass Trap”.

This is the DIY project which incorporates our Art Diffusors®, Cutting Wedge® foam and a couple of isolation hangers into one large free-floating unit, which is acoustically decoupled from the wall.

This particular array was put together by a music producer/bass player for his home. As you can tell from the pics, the construction of this unit was executed beautifully and it’s very close to the original concept drawings.

It’s never too late to get started on your own DIY project.

Visit the Original DIY page to find out how to make your own.

DIY – Treating a Wall – BlockAid® and SoundChannels®

Posted by Acoustics First in Absorption, Animal Shelters, Auditorium, Broadcast Facilities, Classrooms, DIY, Fitness, Government, Gymnasium, Home Entertainment, Home Theater, HOW TO, Media Room, Multipurpose Rooms, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, School & Educational Facilities, Sound proofing, Studio Control Room, Teaching Rooms, Teleconferencing, Theater, Uncategorized, Vocal Booth, Voice Over on July 16, 2015

On many occasions, we get asked about common ways to treat a wall (or walls) either for broadcast, podcast, or other voice recording scenario – where they not only want to tame the reflections within the room, but also block a certain amount of sound coming into – or leaving the room.

On many occasions, we get asked about common ways to treat a wall (or walls) either for broadcast, podcast, or other voice recording scenario – where they not only want to tame the reflections within the room, but also block a certain amount of sound coming into – or leaving the room.

Budget is frequently an issue, major construction is usually unwanted, but effective results are always required.

We’re going to show you how to handle a room upgrade – cut down on the sound transmission and cut the room reflections – all with the same skills required to hang high quality wall coverings! Let’s see how you can cover a wall with BlockAid® vinyl sound barrier to block unwanted sound, then go back and cover that with an absorptive layer of Sound Channels® wall covering to finish it off!

This treatment is not recommended for renters, as this is not an easy upgrade to undo. However, if you have an extra bedroom you are using as Podcast studio, this is a great way to treat it… Let’s get started!

Installing BlockAid®

Good job! Now, take a breather while that dries, and notice how much less sound is passing through the walls. This is when you will notice that the sounds are now coming from under the door, and through the leaky old window. These can be taken care of in different ways…. but the easiest way is the same way you deal with keeping the cold out! Get some weather strip, a door skirt, seal the gaps around the frame of the door, and windows, maybe go out and buy some heavy curtains for the windows… if you have some leftover BlockAid®, you can always get some Industrial Velcro and temporarily stick a piece over the window!

Installing Sound Channels®

That’s it!

This treatment is a common first step in treating many professional broadcast studios – it gives you extra isolation with the barrier and takes the edge of the sound reflections. Many professional environments then go back and add some additional treatments such as bass traps, diffusers, and broadband absorber panels – especially if these studios are planning on bringing in any musical guests.

This isn’t just for home studios. It works great for kids play rooms, bedrooms, home theaters, home gyms, and any place you want to block sound and tame the sound inside the room.

Customize your space as you will, but this treatment is a consistent winner for cost and performance, and is a great way to get started without breaking the bank!

DIY Microphone Shield/Gobo – 2 Minutes (with Video!)

Posted by Acoustics First in Absorption, DIY, HOW TO, Recording Studio, Video, Vocal Booth, Voice Over on May 1, 2015

Acoustics First understands that the Do-it-Yourself spirit in the audio world is alive and well, and here is another one of our contributions to that community.

The personal mic shield… all you need is…

- Foam safe Glue

- a One inch thick, three ring binder

- two 1 foot x 1 foot pieces of foam

- 2 Minutes

Got everything together?

Do you have 2 minutes?

Let’s do this!

Watch the video…

Or follow the steps…

Open the binder and bend the bottom tab flat.

|

|

Spray the Binder and the back of the foam with glue.

|

|

Wait for a few seconds for the glue to get tacky, then carefully stick the foam to the binder – be sure to apply pressure to allow for a strong bond.

|

Give the glue some time to dry.

After the glue sets, slide the rings of the binder over a bare mic stand – the top tab will hold the shield up.

All Done! Just set up your mic and you’re ready to go!

This DIY project is brought to you by Acoustics First – Be inspired and sound great doing it. Enjoy!

You must be logged in to post a comment.