Posts Tagged sonora

Before & After: Video Conference Room

Posted by Acoustics First in Absorption, Customer Feedback, Media Room, Multipurpose Rooms, Offices, Product Applications, Products, Teleconferencing, Video on March 6, 2024

AMC Technology is located in a 5,400 square-foot suite that features a large open office area, a break room as well as several conference rooms.

When Acoustics First® initially met with the AMC team, they had recently moved into the space and were experiencing a number of acoustic problems in the open office area. Although Acoustics First® originally provided recommendations to improve workstation isolation in the open office, once the employees settled into the space, call-clarity issues in the conference rooms had become the much larger concern.

Three of the conference rooms were rudimentarily treated with 1” sound absorbing panels. The other four conference rooms were not treated acoustically and had hard/reflective walls, floors and ceilings. These hard surfaces were most at fault for excessive reverberation, noise buildup and distracting flutter-echoes (“ringing” caused by parallel reflective surfaces). These conditions contributed to an acoustically uncomfortable environment in which speech was hard to understand and conference call clarity suffered.

AMC Technology’s CTO, Anthony Uliano, identified a few goals for potential acoustic remediation. Anthony often works remotely and will call into the conference rooms to talk with team members. The sound of these calls on his side was frequently distorted and individual team members were difficult to understand. Anthony was concerned that clients were experiencing the same intelligibility issues. The primary goal for acoustic treatment was to improve the clarity of conference calls by reducing echoes and excessive reverberation within each conference room. Anthony also mentioned that they were experiencing some isolation problems. Though not a high priority, steps to reduce sound transmission were detailed for future consideration.

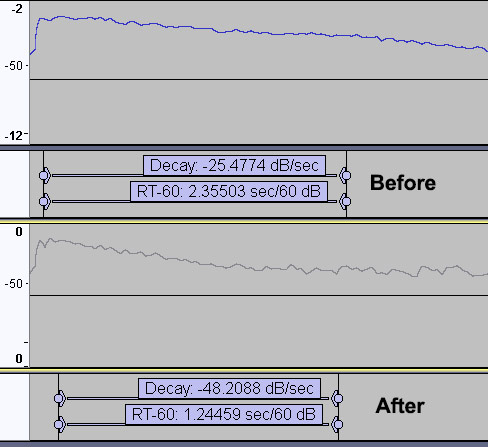

Acoustics First® specified Sonora® wall and ceiling treatment within each conference room to control flutter echoes and reduce reverberation down to suitable levels for conference calls. The video below provides a great snapshot of how the room sounded before and after treatment. Each recording is done in the same room, with the same employee and sitting the same distance from the microphone. The end result is a much clearer and intelligible conversation.

Project: Dogfish Head Brewing & Eats + Reading a Spectrogram

Posted by Acoustics First in Absorption, Customer Feedback, Product Applications, Products, Restaurants on February 12, 2024

Dogfish Head Brewing & Eats is a brewery, restaurant and performance venue located in Rehoboth Beach, DE. This largely reflective space has a wood ceiling, an un-polished concrete floor and walls comprised of drywall, unfinished wood planks (over OSB) and glass. These hard surfaces promote reverberation and early reflections, resulting in a noisy and “muddy” sounding environment.

Acoustics First and Integrity Sound Solutions were brought in to provide solutions to remediate noise level and clarity issues.

The co-owners of Dogfish Head Brewing & Eats and their house engineer identified a few goals for acoustic treatment…

- Reduce “background” noise as levels in excess of 85dBa were common on busy nights. Under these conditions, the sound engineer would push the sound system above 95dBA to maintain music intelligibility. This results in an acoustically uncomfortable environment for patrons and wait staff (which in turn elevate their voices to be heard, further exacerbating noise level issues).

- Control excessive reverberation and latent reflections to improve live-music clarity.

- Minimize visually obtrusive acoustic treatment, particularly on the main wood ceiling.

Acoustics First recorded numerous sine sweeps using the house system (JBL line array and subs) and a calibrated Zoom H4 recorder as the receiver. The sweep was recorded from a number of positions (in front of stage, main dining area, in front of the bar and from the mezzanine level). The following charts are spectrograms of two of these sweeps. Spectrograms are a visual way of representing sound intensity (volume) across a range of frequencies. We can observe how energy levels compare between frequencies and see the response of the speakers and the room at these frequencies over time.

The spectrograms of the sine sweeps show that the house system is very good at producing the full spectrum of frequencies, which gave us more confidence in our analysis.

Reading the Spectrogram – The thickest sweep line (furthest right) is the direct speaker output and the thinner sweep lines are harmonic resonances of the speakers; you’ll notice these bands get further apart as we move up in frequency. The thickness of the sweep, showing sound intensity over time, represents the extent of early reflections. For example, a sweep recorded in an anechoic chamber would have very tight lines.

The first 6dB of early reflections are the most distracting because of their intensity. Reflections arrive slightly late, but at the same frequency, create a “smear” of sound. The faster they decay (<100ms) the more focus you have on the direct source. As you can see, low and mid frequencies stay extremely elevated for the entire 100ms, resulting in a muddy, undefined sound.

Reverberation Time – Measurement & Analysis:

Reverberation Time (RT60) is a metric that is defined as the time it takes for sound to decay 60 decibels (dB) in a room. This is a very important metric for medium-to-large room acoustics as it dictates how well a room will perform for speech and music applications. Generally, a large room with abundant hard surfaces will have a long reverb time. Surfaces that have sound absorptive qualities, like carpet and acoustic panels, reduce reverberation.

Bars/restaurants of this size with live music should have a reverberation time below 1.2s, ideally in the .6-.8s range for “high-intensity” performances, like Rock, Hip Hop or Electronic Dance Music.

We recorded a balloon pop and the subsequent reverb tail and calculated the reverb time based on the decay rate. The results were as follows.

RT60 measurement of 1.656s was recorded at the center of the room. Although this measurement is shorter than initially expected, it is still excessive given the use of the space.

Reverb Prediction:

We entered the dimensions, construction materials and furnishings of the restaurant into our acoustic calculator and made a prediction of reverb times before and after treatment. The modeled “existing” reverberation time and the measured RT60 results we took on-site were very close @ 2000Hz, which gives us confidence in the acoustical model. This means we can add acoustical treatment to the model and accurately predict the results before any changes are made to the actual room and it shows how much improvement you can expect from the recommended treatment.

As you can see, the treated result in the model is within our target RT60 (.6-1.2s) for amplified live-music, resulting in a more suitable performance environment. This treatment would also significantly reduce noise buildup (in a well-treated room, customers and staff will not feel like they have to shout to be heard), further helping control noise levels.

To minimize the amount of visually noticeable treatment, Acoustics First specified fabric wrapped Sonora Panels (http://acousticsfirst.com/sonora-wall-panels.htm) and factory-painted Tone Tiles panels ( https://www.acousticsfirst.com/acoustic-tone-tile-panels.htm) to match the exact wall color. Acoustics First also recommend Sonora Blackboard https://www.acousticsfirst.com/sonora-black-board.htm to “fit” within the metal beams.

Most of the sound absorptive treatment was broad-band in nature. However, Low-Frequency Control (LFC) panels were utilized on the stage wall (behind the line array) to combat the early bass reflections that degrade low-frequency definition. LFC panels are a specialized absorber that focuses squarely on attenuating low-frequencies, below 250 Hz. View our website for more information – https://www.acousticsfirst.com/sonora-lfc.htm

As you can see from the pictures, Integrity Sound Solutions did amazing job with the installation.

What does the client think? Per the co-owners “The sound quality is exponentially BETTER…. The stuff in the beams just disappears!”

The Pickle Factory

Posted by Acoustics First in Absorption, Customer Feedback, Fitness, Gymnasium, Product Applications on November 28, 2023

The Pickle Factory is a massive (22,500 SQFT) indoor recreation facility that was recently renovated to exclusively host pickleball games (previously used for soccer and basket/volleyball matches).

Pickleball utilizes hard paddles and hard-plastic balls, which result in loud “whacks” (upwards of 85dB) when the game is being played. With dozens of paddles active at once, the buildup from these hits can be deafening!

Sonora® Lite PVC Encapsulated wall panels were specified as they are extremely cost effective (approx. half the cost of fabric wrapped panels), offer decent sound absorption and can hold up to the occasional hit from a pickle ball. The monstrous volume of the Pickle factory necessitated covering a large portion of the available wall space to ensure a noticeable improvement.

Although sound absorptive treatment cannot work “magic” and reduce direct sound from the ball impacts, it can reduce overall buildup by as much as 6dB, greatly improving overall acoustic comfort.

From the Installer Lee Hartman & Sons “The client didn’t want the walls covered in sheet rock to get treatment even though it was spec’d in Cameron’s layout. Still got very adequate reverb reduction. Thanks, Cameron, for the layout. With some modifications, it worked out well as you can see. Client is very pleased with the result”

Project: Richmond Friends Retreat Center

Posted by Acoustics First in Absorption, Media Room, Multipurpose Rooms, Product Applications, Products, Worship Facilities on October 26, 2023

Earlier this summer, Richmond Friends Meeting reached out to Acoustics First® for assistance with their new Retreat Center in Amelia, VA. Their multi-purpose community hall was overly live with reverb and echoes, contributing to a poor listening environment. As this space is used for worship, meetings and social events, speech intelligibility is very important and more control was needed to “reign-in” excessive noise.

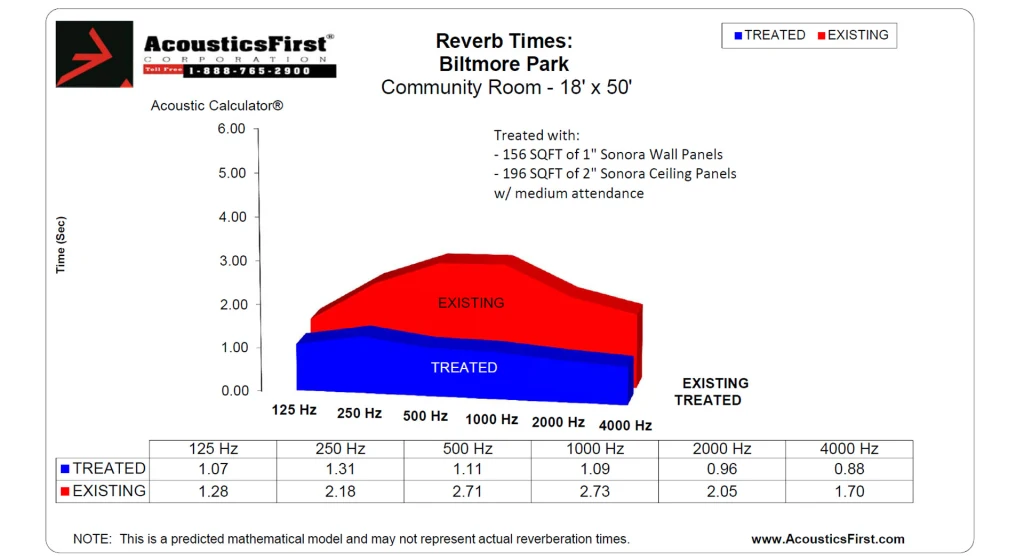

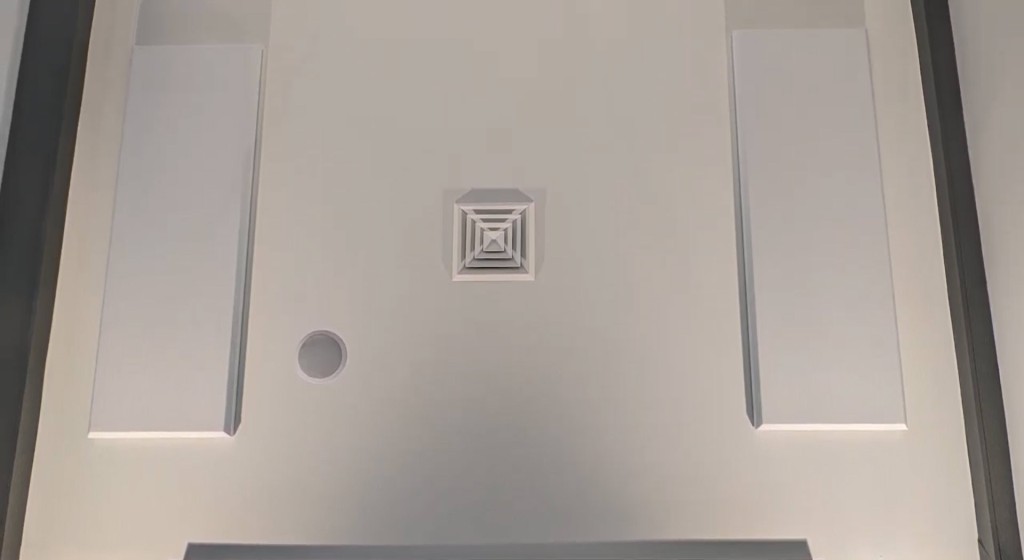

To correct these issues, Acoustics First® recommended a combination of 1” Hi-Impact Sonora® Wall Panels and 2” Sonora® Ceiling Panels. The acoustic design utilized “staggered” 2’x6’ ceiling panels to maximize coverage, in addition to the custom-shaped wall panels which match the slope of the ceiling.

With approx. 400 SQFT of panels between the wall and ceiling, reverb was reduced by approx. 50%, drastically improving speech intelligibility and general room comfort.

The treatment tamed the acoustics of the room, which improved speech intelligibility by reducing the reverberance… and they were very happy with the result!

You must be logged in to post a comment.