Archive for category Music Tracking Room

DIY: Isolation Stand for Speakers and Instrument Amplifiers

Posted by Acoustics First in Articles, Broadcast Facilities, DIY, Home Entertainment, Home Theater, HOW TO, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, Studio Control Room on March 21, 2013

DIY Project – Float your Loudspeakers and Monitors

Keep your Amps and Monitors from shaking the house down!

Instrument amplifiers, loudspeakers, and studio monitors all have the potential to cause structural vibrations. These vibrations can have an adverse effect on the listening environments, and can bleed into other microphones and instruments. Here’s an easy DIY project for floating those noisy guitar and bass cabinets (this project can be scaled up or down – from studio monitors to subwoofers).

Stuff you will need:

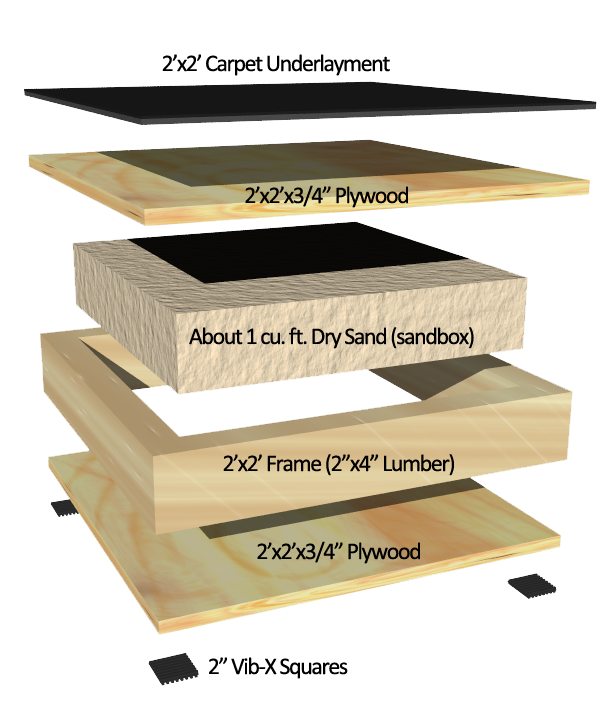

- 2 – 2’x2’x3/4” Plywood (whatever size you want)

- 2’x2’ Carpet Underlayment (Same size as Plywood)

- 2”x4”x8’ Lumber for frame (More if scaling larger)

- About 1 cu.ft. Clean Dry Sand (Sandbox Sand)

- 3’x3’ Industrial Carpet (Enough to cover platform)

- Vib-X Pad to cut at least 4 – 2” Squares for feet

- Construction Adhesive

Simple assembly

- Create Frame and attach to bottom Plywood

- Attach Vib-X feet to bottom

- Fill with Sand

- Attach Plywood top

- Adhere Carpet Underlayment to top

- Carpet Box

This plan is for a 2’x2’ platform. You can scale these or use more than one. Scale with caution – the sand makes these extremely heavy. What you are building is a floating platform. Keeping the sound from being transmitted into the floor below effectively decouples the speaker, making it “float”. In essence, the vibrations are being absorbed before getting to a solid surface, allowing for a more transparent listening experience and keeping the vibrations from interfering with other instruments in the area.

This plan is for a 2’x2’ platform. You can scale these or use more than one. Scale with caution – the sand makes these extremely heavy. What you are building is a floating platform. Keeping the sound from being transmitted into the floor below effectively decouples the speaker, making it “float”. In essence, the vibrations are being absorbed before getting to a solid surface, allowing for a more transparent listening experience and keeping the vibrations from interfering with other instruments in the area.

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. If you are looking for more ways to use the products you have, look to Acoustics First for Ideas. http://www.acousticsfirst.com

————————————————————————————————————————————————————————————

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

Model E Art Diffusors seen in Oddities East/West Marathon Trailer

Posted by Acoustics First in Company Information, Mentions, Music Tracking Room, Recording Facilities, Recording Studio, Studio Control Room, Video, Vocal Booth, Voice Over on December 3, 2012

If you watch closely, you will see the Acoustics First Model E Art Diffusor behind Khalil Ismael in the studio.

Seen @ 2 sec | 7 sec | 10 sec

Oddities East/West Marathon from Tyler Korba on Vimeo.

Video Credit goes to:

VP Creative – Dan Bragg

Creative Director – Tom King

Writer/Producer – Tyler Korba Eye Candy DC

Creative Director – Heather Roymans

Editor – Justin Kanner

GFX – Andy Hsu Clean Cuts

Vocals – Khalil Ismael

Sound Design/Mix – Cadell Cook

For more information on diffusers, please visit: http://www.acousticsfirst.com/diffusers-diffusors.htm

Cutting Wedge Acoustical Foam Featured on 2012 Loudspeaker Sourcebook

Posted by Acoustics First in Anechoic Chambers, Broadcast Facilities, Industrial Facilities, Music Rehearsal Spaces, Music Tracking Room, Press Release, Products, Recording Facilities, Recording Studio, Studio Control Room, Vocal Booth, Voice Over on August 16, 2012

Acoustics First’s Cutting Wedge acoustical foam is featured on the cover of the 2012 Loudspeaker Industry Sourcebook. Acoustical foam can be used in any application that requires sound absorption. This material is used to prevent destructive specular reflections from distorting or color sound. It eliminates room modes and standing waves. Cutting Wedge foam provides more absorption than flat foam by increasing the exposed surface area with its “blade” pattern.

Acoustics First’s Cutting Wedge acoustical foam is featured on the cover of the 2012 Loudspeaker Industry Sourcebook. Acoustical foam can be used in any application that requires sound absorption. This material is used to prevent destructive specular reflections from distorting or color sound. It eliminates room modes and standing waves. Cutting Wedge foam provides more absorption than flat foam by increasing the exposed surface area with its “blade” pattern.

Available in 2″, 3″ and 4″ thick material, this premium acoustical foam can be used to line the cavities of speaker boxes, remove reflections in recording & broadcast studios, quiet machinery and much more. 1’x1′ or 2’x4′ sheets allow the application to be designed however you with to provide optimal coverage for your application.

Available in 2″, 3″ and 4″ thick material, this premium acoustical foam can be used to line the cavities of speaker boxes, remove reflections in recording & broadcast studios, quiet machinery and much more. 1’x1′ or 2’x4′ sheets allow the application to be designed however you with to provide optimal coverage for your application.

http://www.acousticsfirst.com/acoustical-foam-cutting-wedge-classic.htm

For more information, feel free to contact Acoustics First, Toll Free 888-765-2900 | info@acousticsfirst.com | www.AcousticsFirst.com

——————————————————————————————————————————————-

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

Not too many people think about their music stands, but we all have them somewhere. Usually it’s one of those you see to the right – the great, sturdy, utilitarian devices that they are. Unfortunately, there are a couple inherent problems with these:

Not too many people think about their music stands, but we all have them somewhere. Usually it’s one of those you see to the right – the great, sturdy, utilitarian devices that they are. Unfortunately, there are a couple inherent problems with these: Installing a layer of the

Installing a layer of the  Once the barrier is installed, a finish material will need to be installed over this. We would recommend 1/2″ wall board or something simple like the

Once the barrier is installed, a finish material will need to be installed over this. We would recommend 1/2″ wall board or something simple like the  We can also custom manufacture 2″ thick

We can also custom manufacture 2″ thick

You must be logged in to post a comment.