Posts Tagged vibration control

Quiet that fan… Ceiling Fan – With Vib-X

Posted by Acoustics First in DIY, HOW TO, Product Applications, Products on December 10, 2013

Airflow is good. Circulating stagnant air has many health benefits, but what do you do when that ceiling fan is just making too much noise?

To start, check all the normal suspects; is it balanced, cleaned, level, blah blah blah… You’ve probably already checked these anyway. It’s an older fan, the motor hums, because older fans hum. If it’s vibrating through the structure, there may be something you can do to isolate that extra vibration – and at least keep the other occupants happy.

When most people think of Vib-X pads, they think of a musical function; Isolate your speakers, isolate an amplifier, isolate a (insert name of miscellaneous musical gear here)… but there are some really useful everyday functions for this wonderful material. Like keeping that fan from vibrating the entire house!

The simple install may involve a contractor, or at least some one who knows electricity, so you don’t electrocute yourself… but after shutting off the power to the fan, it’s pretty quick. Take down the fan and find the box. Disconnect the box. Cut some Vib-X to separate the box from the wood. Cut some Vib-X squares to use as washers. Remount the box using the diagram, a couple fender washers, maybe a couple optional grommets if you desire – then re-install the fan.

Ceiling fans are usually mounted to an electrical junction box in the ceiling, which is usually just screwed to a ceiling joist or some simple wooden frame. By using the Vib-X to isolate the electrical box from the wood, the vibrations do not directly transfer from the fan into the structure of the house, turning that old, vibrating ceiling fan – into a breath of fresh air.

Simple. Thought so. Don’t forget to balance, level, and clean that ceiling fan while you’re doing all this. Turn that power back on and enjoy the breeze.

DIY: Isolation Stand for Speakers and Instrument Amplifiers

Posted by Acoustics First in Articles, Broadcast Facilities, DIY, Home Entertainment, Home Theater, HOW TO, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, Studio Control Room on March 21, 2013

DIY Project – Float your Loudspeakers and Monitors

Keep your Amps and Monitors from shaking the house down!

Instrument amplifiers, loudspeakers, and studio monitors all have the potential to cause structural vibrations. These vibrations can have an adverse effect on the listening environments, and can bleed into other microphones and instruments. Here’s an easy DIY project for floating those noisy guitar and bass cabinets (this project can be scaled up or down – from studio monitors to subwoofers).

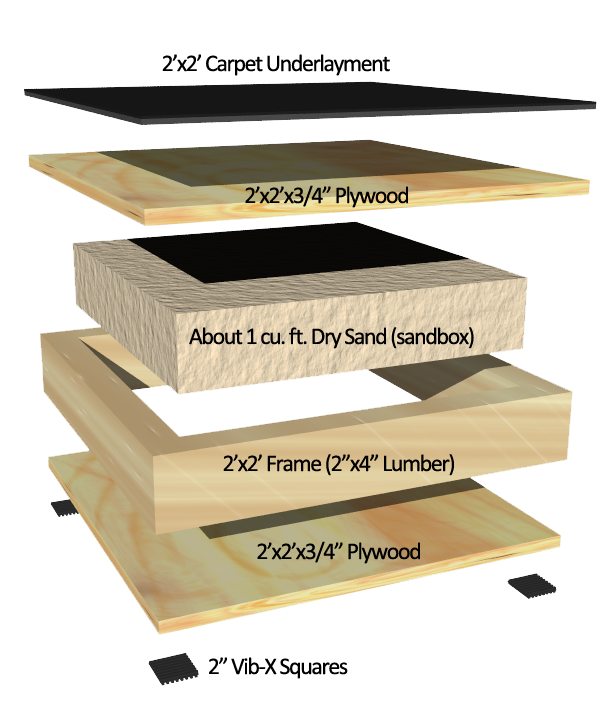

Stuff you will need:

- 2 – 2’x2’x3/4” Plywood (whatever size you want)

- 2’x2’ Carpet Underlayment (Same size as Plywood)

- 2”x4”x8’ Lumber for frame (More if scaling larger)

- About 1 cu.ft. Clean Dry Sand (Sandbox Sand)

- 3’x3’ Industrial Carpet (Enough to cover platform)

- Vib-X Pad to cut at least 4 – 2” Squares for feet

- Construction Adhesive

Simple assembly

- Create Frame and attach to bottom Plywood

- Attach Vib-X feet to bottom

- Fill with Sand

- Attach Plywood top

- Adhere Carpet Underlayment to top

- Carpet Box

This plan is for a 2’x2’ platform. You can scale these or use more than one. Scale with caution – the sand makes these extremely heavy. What you are building is a floating platform. Keeping the sound from being transmitted into the floor below effectively decouples the speaker, making it “float”. In essence, the vibrations are being absorbed before getting to a solid surface, allowing for a more transparent listening experience and keeping the vibrations from interfering with other instruments in the area.

This plan is for a 2’x2’ platform. You can scale these or use more than one. Scale with caution – the sand makes these extremely heavy. What you are building is a floating platform. Keeping the sound from being transmitted into the floor below effectively decouples the speaker, making it “float”. In essence, the vibrations are being absorbed before getting to a solid surface, allowing for a more transparent listening experience and keeping the vibrations from interfering with other instruments in the area.

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. If you are looking for more ways to use the products you have, look to Acoustics First for Ideas. http://www.acousticsfirst.com

————————————————————————————————————————————————————————————

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

Acoustics First releases video on Vibration Isolation

Posted by Acoustics First in HOW TO, Press Release, Product Applications, Sound proofing, Video on February 1, 2013

Acoustics First has conjured up yet another video demonstration. As the fourth in a series designed to help explain common acoustic principles, this video briefly reveals what is necessary to provide vibration isolation.

Acoustics First has conjured up yet another video demonstration. As the fourth in a series designed to help explain common acoustic principles, this video briefly reveals what is necessary to provide vibration isolation.

Vibration isolation can quickly prove to be obtuse and relatively difficult to understand. Common problems like footfall from upstairs neighbors, industrial noise from machinery and HVAC equipment or isolating speakers and scientific devices can require completely different approaches. Most often, an on site assessment should be completed by a qualified engineering professional to determine an appropriate acoustic solution. In many cases the solution will require a modification to the structure and implement more than a single strategy.

This simple vibration demonstration challenges to provide a basic understanding of how acoustical materials may be used to prevent the spread of mechanical noise and vibration through existing structures like walls, floors and ceilings.

In this acoustic demonstration, a surface mounted piezo transducer connected to an analog meter will register levels of sound vibrations transmitted to the table. A vibrating device placed directly on the surface will transmit sound vibrations and resonate loudly throughout the table. These vibrations will register on the analog meter. By inserting isolation materials between the device and the surface, the mechanical sound transmission is reduced and sound no longer registers on the meter.

VIBRATION ISOLATION DEMONSTRATION: Controlling Mechanical Sound Transmission

CLICK HERE FOR MORE ON: VIBRATION CONTROL PRODUCTS

You must be logged in to post a comment.