Archive for category Absorption

Yocumtown gets Peace and Quiet

Posted by Acoustics First in Absorption, Customer Feedback, Gymnasium, Multipurpose Rooms, Product Applications, School & Educational Facilities, Theater, Worship Facilities on May 14, 2014

Yocumtown Church of God had a bit of an issue with their multipurpose room – They couldn’t understand anything anyone was saying.

While the space was designed well with a full court, dampers on the HVAC, a stage, movie screen and a good speaker system – they couldn’t overcome the poor acoustics of the space. A great deal of work had gone into the design and they wanted an unobtrusive way to treat the acoustic problems… enter Acoustics First.

We started the work of gathering information about the space; dimensions, some pictures and a few balloon pops.

Here’s what we got.

Wow! This room is big, all the surfaces are parallel and hard, there’s very little to break up the sound… You can almost imagine what it sounds like.

You actually don’t need to imagine. Here’s a balloon pop. CLICK HERE!

What you’re hearing is about 3.5 seconds of reverberation after the balloon pop. (Not good.)

So, whatever shall we do? How will we tame this space?!?!?! Will they ever be able to have movies for youth groups!?

Sure they will! We have Joe. You remember Joe from the Sabot School Big Room Big Boom Post?

Well, I would say that Joe has a 6th sense for hearing, but since that’s one of the 5 standard ones anyway, we’ll just say Joe has great ears – and they should be. Joe’s been using his ears as his primary tools for the past 40+ years; from Studio Engineer to Acoustic Engineer. His ears are tuned instruments, and we rely on his expertise with them to get the job done right – time and time again. (He also makes a mean spreadsheet.)

So after listening to the room, looking at the data, and running some numbers – Joe magically answers the question of what do they need? (Ok it isn’t magic – Joe’s just really good at this… did I mention his spreadsheet skills?)

So Joe says, “You put 280 – 4’x1′ Cloudscape®baffles up on that ceiling and you’ll bring that room down from about 3.5 seconds to about 1.5 seconds.”

Joe knows.

So, Yocumtown goes from a 3.5 second balloon pop (Here) to a 1.5 second balloon pop (Here).

Not only does it look great…

… But now they say that they can watch movies and it sounds just like you’re in a movie theater.

That’s about the best compliment you can give us.

(And the best compliment I can give Joe is, his calculation for RT60 time was about 1.5 seconds. When I ran the measurement of the “treated balloon pop” – I got 1.501 seconds. This is why we have Joe – he can tell you what you will get, before you even start!)

Barrett’s Technology Solutions has a Happy Easter

Posted by Acoustics First in Absorption, Customer Feedback, Diffusion, Home Theater, Media Room, Product Applications, Theater, Uncategorized on April 20, 2014

Sometimes at Acoustics First we get a call from someone who is so knowledgeable that we can’t help but be tickled that they called us to help them. We received one such phone call from Pete Heskin at Barrett’s Technology Solutions in Naperville, IL.

Pete and his team were putting together an acoustic treatment for a listening room at their facility and wanted the room’s acoustics to really showcase their lineup of high-end audiophile speakers. No joke here – these guys have over 50 years of experience in the audio industry – and they keep on the bleeding edge of audio and video. This treatment is serious acoustic business – and these are some of the most discriminating ears in audio.

Happy Easter guys!

In keeping with their high-standards and cutting edge approach, they were looking for an acoustic treatment that is as visually stunning as it is capable of treating a room containing some of the world’s greatest sound sources. As you can see, the results are simple and elegant.

The room contains an array of Sonora® panels, Silent Pictures® and clusters of ArtDiffusor® Model D‘s to make this space sound as good as it looks. (While all of their gear makes the gear junkies at Acoustics First drool…)

So, if you find yourself near Chicago, or on a “Wayne’s World” pilgrimage, stop into Barrett’s – and if you fancy yourself an audiophile – put your money where your ears are, and hear how discriminating ears listen to music…

… No Stairway to Heaven.

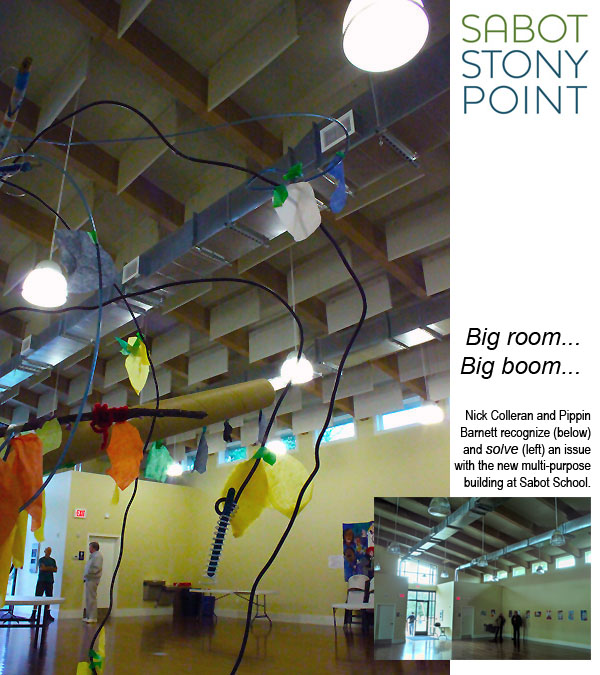

Big Room… Big Boom.

Posted by Acoustics First in Absorption, Art Galleries, Auditorium, Customer Feedback, Gymnasium, Multipurpose Rooms, Music Rehearsal Spaces, Products, School & Educational Facilities, Teaching Rooms on August 22, 2013

When Pippin Barnett contacted Acoustics First about an acoustical issue he was having with a new multipurpose space that was constructed for the Sabot School, he was in desperate need of a solution. This space was needed for functions, activities, art displays, music classes, plays, and more, but was almost completely unusable due to the acoustics.

The large space was well conceived; large open floor plan, hydraulic door to open the space to the courtyard, bathrooms, storage and lots of display space for the student’s artwork and creations. The building was also efficiently constructed using SIPS (Structural Insulated Panel Systems), which created a grand open space with no support pillars.

The large space was well conceived; large open floor plan, hydraulic door to open the space to the courtyard, bathrooms, storage and lots of display space for the student’s artwork and creations. The building was also efficiently constructed using SIPS (Structural Insulated Panel Systems), which created a grand open space with no support pillars.  This space was ready to be used, but there was a problem – whenever they tried using the space, you couldn’t understand what anyone was saying. To say that the acoustics were “not optimal” is like saying that the destruction of the entire universe would be “inconvenient” – an incredible understatement.

This space was ready to be used, but there was a problem – whenever they tried using the space, you couldn’t understand what anyone was saying. To say that the acoustics were “not optimal” is like saying that the destruction of the entire universe would be “inconvenient” – an incredible understatement.

Upon arrival, we took some physical measurements of the space to calculate the surface area and volume of the room, as well as got some acoustic measurements.

Click here for a balloon pop before acoustic treatment.

Whoa… Big Boom! What you are hearing is a 3+ second RT60 time; That’s more than 3 seconds of time that the sound lingers in your space at a level audible enough to interfere with other sounds.

Which is “Inconvenient,” and “Not Optimal.”

So with some magic calculations performed by Joe Horner over at the quietest office in Acoustics First,(no really – he likes it really quiet,) a solution was developed to create a space that sounded as good as it looked.

Joe prescribed 100 2’x4′ Cloudscape ceiling baffles as well as 157 sq ft of 1″ thick Sonora Wall panels to cover the solid hydraulic door – and we listen to Joe (he’s done this a lot!)

So, a short while later, the Baffles and Panels are installed and we receive an e-mail from Pippin…

“I’d say you were right on the money!”

Click here for a balloon pop after acoustic treatment.

RT60 from 3+ seconds down to right about 1 second. I’d say that’s right on the money too, Pippin!

The Sabot School regained the use of its space and everyone lived happily ever after.

I love happy endings.

DIY: Back Wall Diffuser Array/Bass Trap

Posted by Acoustics First in Absorption, Auditorium, Broadcast Facilities, Diffusion, DIY, Home Entertainment, Home Theater, HOW TO, Media Room, Multipurpose Rooms, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Products, Recording Facilities, Recording Studio, Restaurants, Studio Control Room, Teleconferencing, Theater, Vocal Booth, Voice Over, Worship Facilities on June 20, 2013

Getting more out of your back wall diffuser array with a simple hanging DIY array/bass trap.

One of the big “back wall” questions people have is “If I have a large diffuser array, how can I get the bass trapping I need?” A great answer to this question is to turn the entire array into a hanging bass absorber. If you are already planning on getting diffusion for your back wall, here is a great way to use that wall space for more than just diffusion.

Stuff you need:

- 4’x 8’ sheet of 3/4” Plywood

- 32 sq/ft of 4” Cutting Wedge® Classic Foam (Or similar absorber)

- 8 x Art Diffusers® – Model C (or Model F, Quadrapyramid™, or other comparable diffuser)

- 2 x IsoHangers

- 2 x Heavy rings (Think big Curtain Rings or Hanging Wire will also work)

- 2x Closet Rod/Shelf Brackets

- 2 x 7/8” wood screws and fender washers

- Construction Adhesive (Make sure it’s safe for Foam)

Assembly instructions

- Screw the two IsoHangers to the plywood, using a fender washer on each screw. These should be about an inch in from each end -drill small pilot holes first. (These will be used to hang the panel, this side will be designated as the back from here on out.)

- Use Construction adhesive to attach the Cutting Wedge® Foam to the back of the panel in a checkerboard pattern (each panel 90° rotated from adjacent)

- Use Construction adhesive again to attach the 8 Diffusers to the front of the Plywood (Follow the installation instructions for adhesive placement)

- Attach the Rings or Wire to the free end of the IsoHangers.

What you have created is a hanging panel that will diffuse mid-high frequencies and trap the lows. The hanging mass absorbs low frequency energy by moving slightly when pushed by the energy of the Low frequency Waves. The rear facing fiberglass also absorbs low frequencies by dampening the panel, but it also absorbs any of the waves that happen to get trapped behind the panel.

Hanging the Diffuser/Trap Assembly

- Measure and attach the Closet Brackets to the Wall – Use appropriate anchors! If you have standard or double wall construction without Resilient Channels, use the studs – The IsoHangers will keep vibrations from transmitting through the wall.

- Hang the panel on the Closet Brackets using the rings/wire with the Diffusers facing you and that’s it!

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. For those customers who are planning on purchasing diffusers to make an array, or maybe already have an array and are looking to try a new configuration – this project may be what you’re looking for.

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. For those customers who are planning on purchasing diffusers to make an array, or maybe already have an array and are looking to try a new configuration – this project may be what you’re looking for.

A little History…

If you embark on this little construction project, you will be constructing studio elements that have remained basically unchanged since at least the early 1970’s. Hanging plywood wrapped in studio foam or fiberglass has been used “behind the curtains” of many of the top studios for effective bass control for over 40 years – just no one has ever seen it, as it has been hidden in walls; masked as a false wall of fabric stretched across wooden louvers!

————————————————————————————————————————————————————————————

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

You must be logged in to post a comment.