Archive for category Music Rehearsal Spaces

DIY: How to quiet down that noisy equipment rack

Posted by Acoustics First in Absorption, Auditorium, Broadcast Facilities, Data Centers, DIY, Government, Home Entertainment, Home Theater, HOW TO, Media Room, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, Sound proofing, Studio Control Room, Vocal Booth on May 2, 2013

Take a few seconds and DIY fix some of the common problems with using equipment racks!

Not too many people think about their equipment racks, but many of us use them. Usually it’s something like what you see to the right – the great, sturdy, utilitarian box. Unfortunately, there are a couple inherent problems with these:

- Ringing – The metal resonates causing a ringing effect – may be masked by program material.

- Reflections – many times your rack is near sound sources causing reflections off the hard surfaces.

- Noise – Fans and other devices in the rack can make noises that are disruptive to recording.

Here are a few DIY fixes for these common problems.

- Composite foam with adhesive backing is perfect for stopping the ringing of filler panels.

- FireFlex™ acoustical foam the inside of your rack to keep the noise down.

- Use some Composite Foam to line your trays, drawers and shelves to keep items from rattling around inside the case.

- Cover your rack in Sound Channels® fabric to keep the case from causing harsh reflections.

- Make a temporary cover for the front and back with BlockAid® sound barrier with minimal ventilation cut-outs to use during takes if rack-borne noise is problematic.

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. If you are looking for more ways to use the products you have, look to Acoustics First for Ideas. http://www.acousticsfirst.com

————————————————————————————————————————————————————————————

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

DIY: Isolation Stand for Speakers and Instrument Amplifiers

Posted by Acoustics First in Articles, Broadcast Facilities, DIY, Home Entertainment, Home Theater, HOW TO, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, Studio Control Room on March 21, 2013

DIY Project – Float your Loudspeakers and Monitors

Keep your Amps and Monitors from shaking the house down!

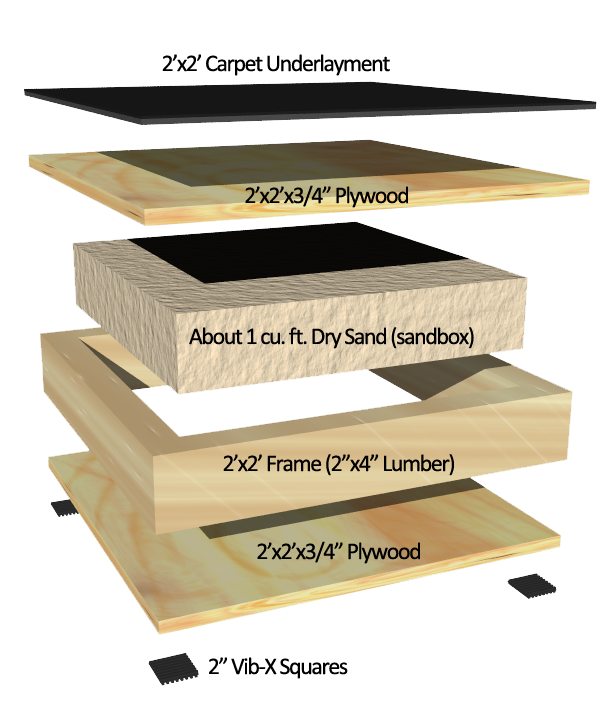

Instrument amplifiers, loudspeakers, and studio monitors all have the potential to cause structural vibrations. These vibrations can have an adverse effect on the listening environments, and can bleed into other microphones and instruments. Here’s an easy DIY project for floating those noisy guitar and bass cabinets (this project can be scaled up or down – from studio monitors to subwoofers).

Stuff you will need:

- 2 – 2’x2’x3/4” Plywood (whatever size you want)

- 2’x2’ Carpet Underlayment (Same size as Plywood)

- 2”x4”x8’ Lumber for frame (More if scaling larger)

- About 1 cu.ft. Clean Dry Sand (Sandbox Sand)

- 3’x3’ Industrial Carpet (Enough to cover platform)

- Vib-X Pad to cut at least 4 – 2” Squares for feet

- Construction Adhesive

Simple assembly

- Create Frame and attach to bottom Plywood

- Attach Vib-X feet to bottom

- Fill with Sand

- Attach Plywood top

- Adhere Carpet Underlayment to top

- Carpet Box

This plan is for a 2’x2’ platform. You can scale these or use more than one. Scale with caution – the sand makes these extremely heavy. What you are building is a floating platform. Keeping the sound from being transmitted into the floor below effectively decouples the speaker, making it “float”. In essence, the vibrations are being absorbed before getting to a solid surface, allowing for a more transparent listening experience and keeping the vibrations from interfering with other instruments in the area.

This plan is for a 2’x2’ platform. You can scale these or use more than one. Scale with caution – the sand makes these extremely heavy. What you are building is a floating platform. Keeping the sound from being transmitted into the floor below effectively decouples the speaker, making it “float”. In essence, the vibrations are being absorbed before getting to a solid surface, allowing for a more transparent listening experience and keeping the vibrations from interfering with other instruments in the area.

This simple DIY project is provided as a way for our customers to learn better ways to use our products and get more value out of the products they buy. If you are looking for more ways to use the products you have, look to Acoustics First for Ideas. http://www.acousticsfirst.com

————————————————————————————————————————————————————————————

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

Acoustics First’s acoustical wall fabric saves $Green$ while being Green!

Posted by Acoustics First in Art Galleries, Auditorium, Broadcast Facilities, Classrooms, Fitness, Government, Gymnasium, Home Entertainment, Hospitals, Medical Facilites, Multipurpose Rooms, Museums, Music Rehearsal Spaces, Offices, Press Release, Products, Recording Facilities, Restaurants, School & Educational Facilities, Studio Control Room, Teaching Rooms, Teleconferencing, Theater, Universities, Vocal Booth, Voice Over, Worship Facilities on October 18, 2012

For Immediate Release

Acoustical wall fabric saves $Green$ while being Green!

Sound Channels® acoustical wall fabric is manufactured from 100% Post-Consumer Recycled material, making this a quick ship, easy, no thought acoustic solution.

Sound Channels® acoustical wall fabric is manufactured from 100% Post-Consumer Recycled material, making this a quick ship, easy, no thought acoustic solution.

Sound Channels® is applied directly to vertical surfaces, is easy to cut and installs like wall carpet. This absorptive wall fabric is a great choice to moderate speech frequencies in any application. Great to soften sound in conference rooms, distance learning, offices, and day care facilities, this material can also be used as a base layer in home theaters, recording studios and broadcast facilities.

Not only is this economical acoustical treatment available in countless colors, it is manufactured from recycled materials, reducing environmental impact!

Sound Channels in manufactured using Eco-fi fibers. Eco-fi is a high-quality polyester fiber made from 100% certified recycled plastic bottles. It can go into any textile product such as clothing, blankets, carpets, wall coverings, auto interiors, home furnishings, and craft felt. Eco-fi can also be blended with other fibers, such as cotton or wool, for enhanced qualities.

AN EASY GUIDE: 15 bottles = 1 yard of wall covering

Why buy Eco‐fi products?

We have the capacity to keep billions of plastic bottles out of the world’s landfills each year by using post-consumer plastic bottles instead of virgin materials in the fiber manufacturing process. By doing this, we can lower harmful air emissions and save millions of barrels of oil from being used which, in turn, reduces the harmful effects of acid rain, global warming, and smog. Fabrics made from Eco-fi fiber are chemically and functionally nearly identical to those made from non-recycled fiber. The difference is that Eco-fi fiber is made without depleting the Earth’s natural resources. With properties such as strength, softness, shrinkage-resistance, and colorfastness, market applications for Eco-fi products are expanding every day.

Click here for more information on the Sound Channels acoustical wall fabric.

http://www.acousticsfirst.com/sound-channels-wall-covering.htm

——————————————————————————————————————————————-

Acoustics First Corporation supplies acoustical panels and soundproofing materials to control sound and eliminate noise in commercial, residential, government, and institutional applications worldwide. Products include the patented Art Diffusor®, sound absorbers, noise barriers, acoustical fabrics and accessories. Acoustics First® products are sold for O.E.M applications, direct, and through dealers. For more information on acoustical materials and their application, please visit www.AcousticsFirst.com or call Toll Free 1-888-765-2900 (US & Canada).

|

www.AcousticsFirst.com Acoustics First Corporation PH: (804) 342-2900 |

Sign up for Future Press Releases http://eepurl.com/hxZCs |

Not too many people think about their music stands, but we all have them somewhere. Usually it’s one of those you see to the right – the great, sturdy, utilitarian devices that they are. Unfortunately, there are a couple inherent problems with these:

Not too many people think about their music stands, but we all have them somewhere. Usually it’s one of those you see to the right – the great, sturdy, utilitarian devices that they are. Unfortunately, there are a couple inherent problems with these:

You must be logged in to post a comment.