Posts Tagged acoustical materials

Sonora® Wall Panels on the Ceiling?

Posted by Acoustics First in Absorption, HOW TO, Product Applications, Products, Restaurants on February 25, 2022

Sometimes you just don’t have the wall space for acoustic treatment. When this is the case, you will often see treatments move to the ceiling… but what do you do if you have lower ceilings, or many ceiling fans and fixtures?

This ceiling was sloped toward the massive windows on the outside wall, and it had lights and fans running right up the center. Complicating things further, the opposite wall had sconce lighting, doorways, HVAC, and even more windows. Finally, the floor was not carpeted to facilitate cleaning – as is the norm in many dining spaces.

Direct-mount acoustic panels are a great solution in these scenarios. Here we see an array of 4’x4’x2″ Sonora® panels attached to the ceiling in rows running down the length of the space. While our Tone Tiles® are often selected for their ability to blend in aesthetically, this particular installation proves that Sonora® panels wrapped in fabric are also a solid choice.

Sound Diffusion vs. Absorption in Worship Environments

Posted by Acoustics First in Absorption, Articles, Diffusion, Product Applications, Uncategorized, Worship Facilities on January 25, 2022

Cathedrals, mosques, synagogues and temples are often decorated with an abundance of architectural details (deep coffers, arches, columns, sculptures, intricate engravings etc.). These features are not only beautiful to look at, but also serve the vital acoustic purpose of sound diffusion. Large, uninterrupted spans of hard, flat surfaces reflect sound in a singular, specular wave, which creates discrete echoes and comb filtering (In acoustics, comb filtering is when a delayed reflection interferes with, and distorts the original sound wave). These conditions can contribute to an acoustically uncomfortable environment, in which speech is difficult to understand, and music can be hard to perform and enjoy. Irregular surfaces, on the other hand, scatter these reflections, minimizing comb filtering and distracting echoes. In a “diffused” worship environment, speech is intelligible, music is clear and warm, and there is a sense of envelopment which greatly enhances the congregants’ worship experience.

Absorptive treatment can also be used to control echoes and harmful reflections. Instead of redistributing reflections, these “fluffy” materials (drapery, padded pews, acoustic panels etc.) reduce the overall sound energy from the reflections in the room. However, using to too much sound absorption in a room can often make a space sound ‘dry’ or ‘dead’. Determining whether your space needs absorption, diffusion, or a combination of both is dependent upon the acoustic properties of the space, as well as the type of worship service being conducted.

Acoustic Properties of the Worship Space: Reverberation, a principle acoustic factor, is the sound energy that remains in a listening environment as a result of lingering reflections. The dimensions, construction materials, and furnishings of a given worship space determine its reverberation time (RT or RT60). Large halls with reflective materials (glass, wood, concrete) have longer reverb times, while small rooms with absorptive materials (drop acoustic ceiling, carpet, curtains etc.) will have shorter reverb times. Incorporating sound absorptive materials, Such as fabric wrapped acoustic wall panels, is often the best way to reduce the overall reverberation in a room to a suitable level. However, the target reverb time also depends on the nature of the worship service being conducted in a particular space.

Type of Worship Service: Ideal reverb times for worship environments vary widely. Non-musical, spoken-word worship requires a very short reverb time (.5-.8s range), ensuring that speech is intelligible. At the other end of the spectrum, cathedrals can tolerate an extremely long reverb time (2s and above) due to the traditional nature of their liturgy. Choir, organ and plainchant worship will actually benefit from longer reverb times that create a sense of ambience and spaciousness by sustaining musical notes. These spaces will often lack a sound system, and instead utilize the hard surfaces to propagate sound throughout the room.

Traditional worship may be enhanced by long reverb times, but contemporary worship requires a significantly shorter reverb time. In these environments, drums, guitars, bass and other amplified instruments are critical to the high intensity worship experience, but have far different acoustical needs compared to the choir and organ in a more traditional service. Contemporary “high impact” churches require a reverb time in the .8-1.3s range to ensure that the music won’t become too “muddy” and indistinct. Contemporary churches must also be more cognizant of late specular reflections (slap echoes) which can inhibit the timing of musicians and contribute to poor music clarity.

Let’s take a look a few common scenarios when it comes to treating traditional and contemporary worship spaces.

Scenario 1: Conversion from Traditional to Contemporary worship

A growing contemporary church moves into a larger, traditional sanctuary and is confronted by a raucous acoustic environment during their first rehearsal… This “live” space was perfect for traditional music, but is not conducive to a “high impact” contemporary worship service. To reduce the excessive reverberation and distracting echoes, sound absorption should be added to the rear wall (opposite stage) and side walls. Also, if using on-stage monitors, the stage walls should be treated to manage stage volume. Spot diffusive treatment that provides low-frequency absorption would also be beneficial. A good choice for this would be traditional ‘barrel’ diffusers. These are one of the oldest tried and true solutions for controlling bass issues in a performance space. Also, since these units function as both absorbers and diffusers, you get the benefits of both.

Scenario 2: Mix of Traditional and Contemporary worship services.

A worship facility decides to offer a contemporary service in addition to their traditional services… As more absorption is introduced to cut down on distracting reflections, we want to retain the envelopment and spaciousness which benefits congregational singing and traditional worship music. Sound diffusive treatment would be a great way to control echoes and specular reflections, while keeping the energy in the space. A mix of absorption and diffusion is usually best. Multipurpose spaces can also benefit from variable acoustic treatment which allows the room to “adapt” to each service, but that is a subject for another article.

Scenario 3: Poor Music Clarity in Traditional Worship space

A traditional worship space renovates their facility by adding thicker carpet, padded pews and a drop acoustic ceiling… All of a sudden, their once lively space feels “flat” and dull. Acoustic instruments are more anemic, less distinguishable and choirs have a difficult time blending and tuning. To “liven up” the space, replace sound absorptive materials with diffusers. For example, replace 1/3rd of the acoustic ceiling tiles with a combination of gypsum tiles and lay-in diffusers. These days, there are wide variety mid-range quadratic sound diffusers available for drop tile ceiling grids, as well as the more traditional barrel and pyramidal diffusers.

Sound diffusion can often seem a little mysterious compared to sound absorption. This is at least partly because sound diffusion is a more complex and multi-dimensional phenomenon compared to the more easily quantifiable sound absorption. However, sound diffusion is often times the missing piece of an acoustic puzzle: its benefits can help a bad room to sound good, or a good room to sound great!

Sonora® Panels help Citizen Heights Church

Posted by Acoustics First in Absorption, Articles, Product Applications, Worship Facilities on July 13, 2021

Citizen Heights Church found a great facility to move into, even during a global pandemic. However, a major obstacle was that the facility had a traditional cathedral ceiling and a nearly 6 second reverb time was not compatible with their high-energy modern services. To address this issue, they included custom Sonora® panels in their overhaul. This decision helped take their 6 second reverb time down to an incredible 1.5 seconds – creating a space that maintains a level of intelligibility which would have been impossible otherwise.

Read the full story here.

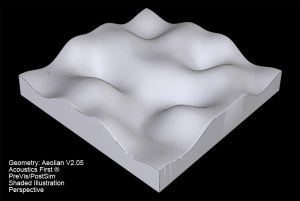

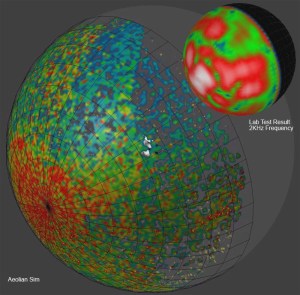

Introducing the Aeolian™ Diffuser

Posted by Acoustics First in Diffusion, Products on July 11, 2017

Acoustics First® is pleased to announce our latest creation: The Aeolian™ Sound Diffuser. In some ways a simplified version of our popular Art Diffusor® Model D, the Aeolian™ is the latest in our line of ‘Organic Quadratics’. Part of the Aeolian’s™ unique design comes from its use of “implied symmetry”. Although the edges are all asymmetric, the height variations are just subtle enough to create an illusion of symmetry when installed in a standard 15/16” grid, or spaced appropriately on a wall. The lack of a uniform edge also has added acoustical benefits in the way of “randomness”.

The development process for the Aeolian™ was similar to that of our ‘Model D’. Various 3D models were created and refined, after which we ran acoustical simulations. Once we settled on what we considered the optimum design for what we were going for, a full scale 3D model was printed for lab testing. With the ‘real world’ test results in hand, confirming our predicted results, we set about making the final mold, and this new diffuser was born.

The Aeolian™ Diffuser is class A thermoplastic, and 4 lbs. per unit.

Nominal size is 23-3/4” x 23-3/4” with a depth of 5.1”.

Demystifying Acoustic Data: Part 2 – Test Material Mounting

Posted by Acoustics First in Absorption, Home Entertainment, Home Theater, Products, Recording Facilities, Theater on October 13, 2016

For anyone new to the world of acoustics, there is a multitude of terms, coefficients and numbers that are thrown around. This flood of information can seem intimidating, especially to beginners. In this series, acoustician Cameron Girard of Acoustics First® hopes to help you distinguish between what’s useful and what’s not.

Part 2: How Mounting in Testing Affects Sound Absorption Data

As I discussed in my previous article, the best way to compare the performance of sound absorbing panels is by referencing the Sound Absorption Coefficient (SAC) and Noise Reduction Coefficient (NRC). However, these coefficients are often used as marketing tools. Be on the lookout for companies that list absorption coefficients and NRCs without mention of a particular testing standard or mounting method. It’s vital to check for this information, as direct comparisons to competitors and other materials can only be made if their testing procedures are the same.

The sound absorption of a material that covers a flat surface not only depends on the physical qualities of the material but also on how the material is mounted during installation. The mountings specified in laboratory tests are intended to simulate conditions that exist in normal use, such as direct wall mounting and installation into a ceiling grid.

Many materials for treatment of walls or ceiling are tested using what is called Type ”A” mounting. Type ”A” mounting means the test specimen was placed directly on the test surface of the reverberation chamber. Lay-in ceiling tiles, on the other hand, are often tested using ”E400” mounting. The ”E” designates a sealed air space behind the specimen (simulating the air gap between a dropped tile ceiling and the structural ceiling) and the number after the ”E” is the depth of the airspace in millimeters. The airspace behind the acoustic material affects the sound absorption by acting as a bass trap. The deeper the cavity behind the panels is, the lower the fundamental of the “trapped” frequencies will be.

To see what this look like in terms of actual numbers, let’s take a look at how different mounting methods effect the sound absorption coefficients of Acoustics First’s HiPer® Panel (a low-profile, composite absorber/diffuser panel).

Since the HiPer® Panel can be used effectively in multiple applications; we had it tested in accordance to the two most-common mounting procedures, Type E-400 and Type A. The results of the laboratory tests are as follows:

|

Product Info |

Sound Absorption Coefficients |

||||||||

| Product Name | Thickness | Mounting | 125Hz | 250Hz | 500Hz | 1kHz | 2kHz | 4kHz |

NRC |

| 1″ HiPer® Panel | 1″ | E-400 | 0.43 | 0.28 | 0.51 | 0.76 | 0.99 | 1.10 | 0.65 |

| 1″ HiPer® Panel | 1″ | A | 0.09 | 0.28 | 0.78 | 0.75 | 0.94 | 0.85 | 0.70 |

As you can see from the chart, the sound absorption coefficient at 125 Hz varies greatly between E-400 mounting (SAC of .43) and Type-A mounting (SAC of .09). If mounting the HiPer® Panel in a ceiling grid, with a sizable airspace, you can expect significant low-frequency absorption, but mounting it on a wall (Type-A) will result in much less absorption at 125Hz.

Other mounting methods are available, but are not used as frequently. Here are some of the basic mounting designations (See ASTM E795 for more information.)

Type A mounting – Test specimen laid directly against the test surface (wall panel on drywall).

Type B mounting – Test specimen cemented directly against the test surface. Type B mounting is intended to simulate acoustical ceiling tiles or other sound-absorptive products adhered to a hard surface with an adhesive.

Type C Mounting—Test specimen comprising sound-absorptive material behind a perforated, expanded, open facing or other porous material.

Type D Mounting—Test specimen mounted on wood furring strips.

Type E Mounting—Test specimen mounted with an air space behind it (dropped tile ceiling).

As we’ve discussed, acoustical data can vary greatly depending on the mounting method used during testing. Acoustics First tries to include as much information about testing procedures as possible, because we feel an informed client makes the best client.

Contact Acoustics First for your all your sound control needs!

You must be logged in to post a comment.