Archive for category Teaching Rooms

Acoustical Considerations for Classrooms

Posted by Acoustics First in Absorption, Articles, Classrooms, Product Applications, Products, School & Educational Facilities, Teaching Rooms on September 19, 2024

Poor classroom acoustics has long been the invisible problem that has the farthest reaching implications for learning. Excessive noise and reverberation degrade speech intelligibility, resulting in reduced understanding and therefore reduced learning. In many classrooms in the United States, the speech intelligibility rating is 75% or less. That means, in speech intelligibility tests, listeners with normal hearing can only understand 75% of the words read from a list. Imagine reading a textbook with every fourth word missing. Wouldn’t that make comprehension near impossible? Fortunately, poor classroom acoustics can usually be remedied with some basic knowledge and commercially available treatment. But before getting into specific treatment, let’s go over some basic acoustic principles.

Noise

Obviously, it’s difficult to understand what the instructor is saying when there is a lot of naturally occurring noise in the room. A glut of factors can be considered noise sources, including HVAC “rumble”, traffic outside the building and students moving in their chairs. These sources contribute to a “noise floor” that makes understanding speech very difficult. Since there is no one “cure-all” for an excessive noise floor, it is often best to seek the assistance of a professional acoustical consultant to properly diagnose and find a solution to these issues.

Reverberation: Undesirable vs Useful Reflections

When not attributed to a noise issue, the culprit of poor classroom acoustics is often excessive reverberation. In simple terms, reverberation is the sound energy that remains in the listening environment as a result of lingering reflections. As mentioned before, these reflections can easily interfere with speech intelligibility. As you may have experienced at some point, it can be difficult to understand what is being said when reflections from old information cover up what is newly spoken.

The reverberation time (RT or RT60) is used to determine how quickly sound decays. The RT is dependent upon the volume and surface materials of a given room. Large spaces with hard materials (tile, drywall, etc.) have longer reverberation times, while small rooms built with “softer” materials sound more “dead”. Ideally, classrooms should have relatively short RT’s, somewhere in the .6-.8 second range.

A long reverberation time is not the only factor that should be considered when treating a classroom with poor acoustics. Flutter echo is a particularly significant problem when it occurs between the side walls at the front of the classroom where the teacher is speaking. This condition can be heard as a “ringing” sound (when one claps) as the sound rapidly bounces back and forth between two parallel walls. Flutter and other discrete echoes are considered “undesirable reflections” and should be controlled with absorptive or diffusive materials.

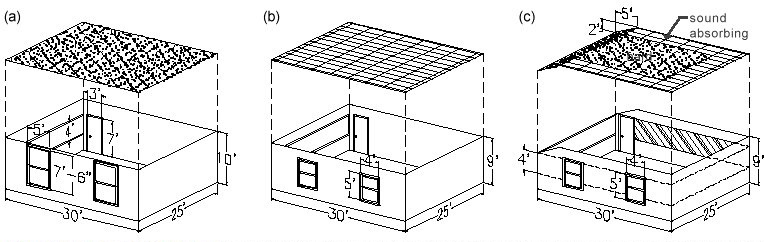

Not all reflections are bad though. There are “useful reflections” that reinforce spoken word, rather than cover it up. The teacher’s voice can be propagated throughout the room by shaping a sound reflecting gypsum board ceiling over the front of the room or by making the center of the ceiling a hard, reflecting surface (see figure 1). This will help project the speaker, so they don’t have to strain their voice to be heard over the students.

Reducing Reverberation

Often reducing the dimensions of a classroom to attain a more suitable reverberation time is not feasible, but one can improve the acoustics by introducing sound absorptive materials. Typical classrooms usually have a dropped “acoustical” ceiling that has some absorptive qualities. In classrooms that don’t have this ceiling, reverberation can be reduced by installing an acoustical ceiling or a number of fabric faced fiberglass panels, like Sonora® Ceiling Clouds. Likewise, if there isn’t carpeting in the room, you can marginally reduce the reverberation time by installing sound absorptive flooring.

Wall treatment: Acoustic Panels

If the ceiling and floor are at least rudimentarily treated, then hard walls are usually at fault for poor speech intelligibility. Absorptive wall panels, like Acoustics First Sonora® panels, are a common treatment to control lateral reflections and reverberation.

These panels are popular because they can be customized with a variety of colors, edge designs and fabric facings. They also can come with a high-density fiberglass adder that improves durability. In classrooms, these “Hi-impact” panels are particularly useful because the adder allows for the panels to be used as tack boards. This brings an extra level of functionality to the panels outside of their absorptive properties.

Though wall panels are a perfectly suitable treatment, uncovered areas between the panels can sometimes allow a few hard reflections and/or flutter echo to still occur (although full treatment of the walls would likely result in a room sounding too “dead”). For these situations, Acoustics First often recommends Sound Channels® acoustic wall fabric.

Acoustical Wall Fabric

In many instances, acoustic wall fabric is actually a viable alternative to traditional wall panels. Unlike a typical “wall carpet”, Sound Channels® is made of 100% recycled content and has ridges to increase surface area and absorption. Perhaps most importantly, the uniform coverage you get by treating the walls with acoustic wall fabric eliminates the flutter/slap from reflective parallel walls (without making the space too “dead”). Acoustic wall fabrics are generally light weight and most can be put up just like any other wallcovering.

Also of note are the additional benefits when using Sound Channels® in early education classrooms. The effective range that this wall fabric controls is the higher speech frequencies, which is the ideal range for classrooms with younger children (there are not many bass/baritone kindergarteners). Another advantage is in keeping the treatment clean. Wall panels may suck up sound, but they can also absorb fluids (like the occasional juice box). Sound Channels®, on the other hand, is resistant to moisture, mildew and rot. It is also is non-allergenic, easy to clean, and is highly resilient to common wear.

Acoustical Considerations for Classrooms

Although this knowledge has been around for decades, classrooms across the country continue to be plagued by a lack of acoustical forethought. Perhaps as this information becomes more readily available to architects, contractors, administrators and teachers we will begin to see (and hear) better sounding classrooms. School is challenging enough on students and teachers as it is, let’s not compound their daily obstacles by continuing to overlook classroom acoustics.

(Originally published in Christian School Products Magazine – November, 2015)

Taming the Cube with Cloudscape®

Posted by Acoustics First in Absorption, Classrooms, Customer Feedback, Manufacturing, Media Room, Product Applications, School & Educational Facilities, Teaching Rooms, Universities on October 21, 2022

When the University of the Pacific reached out to help tame the acoustics of their makerspace called “The Cube”, many different concerns were underlined about the space, its uses, and the problems they faced.

These concerns covered more than just the room dimensions – size, height, HVAC, glass walls, etc…. there were functional requirements for collaboration, classes, and workshops. The overwhelming acoustic problems involved the near constant noises generated by the vast array of equipment in this space – sewing machines, large format printers, plotting cutters, 3D printers, scanners, and every other modern tool for allowing the creative minds at their school to create. It was a cacophony of stepper motors, fans, and moving parts – which made collaboration very difficult.

The other parameter that needed to be maintained was the ability to reconfigure the layout of the equipment without affecting the acoustic treatment in the space. This removed almost all of the walls in the space as possible locations for treatment. This left the ceiling as the only viable space left for treatment, but with an array of lights and exposed HVAC systems, there were few treatments that would be easy to implement and still be effective.

The decision was made to creatively weave Cloudscape® Baffles into all the spaces available in the ceiling. Dodging duct-work and suspended lighting rails was made possible with careful planning and execution – and the results were immediately notable. (Also noticeable was that the baffles had very little impact on the lighting which is vital in any makerspace.)

“…The sound baffles you recommended finally got installed in my makerspace about two weeks ago and I wanted to send a quick thank you since they’ve made a very noticeable acoustic difference to the room, and it’s a lot more pleasant in here now. “

Chris Crawford – Innovation Spaces Manager (University of the Pacific)

Silent Pictures® goes BIG for Ditch Witch®

Posted by Acoustics First in Absorption, Classrooms, Customer Feedback, Product Applications, School & Educational Facilities, Teaching Rooms, Uncategorized on September 16, 2021

When Ditch Witch® needed to acoustically treat their training room, they had a big and bold idea – take a cool promo photo and use that to make a Silent Pictures® mosaic! The required scale made it easier to break up the photo into a 3’x3′ matrix, which also eased the shipping and installation process! The final product (at over 9 feet tall and 15 feet wide) is imposing, and while it isn’t quite life-sized, the impact is indeed massive!

“Thank you so much for all the help you and your team did on this project. Our training room is complete now.

Ditch Witch Midwest

We are over the moon happy.”

Little Safari Day Care – creating peace (and quiet), one pyramid at a time.

Posted by Acoustics First in Absorption, Classrooms, Customer Feedback, Multipurpose Rooms, Product Applications, School & Educational Facilities, Teaching Rooms on August 11, 2021

With more parents returning to the office, we’ve recently received a handful of treatment requests from day-care facilities dealing with an influx of boisterous children.

Little Safari Day care reached out to us in July 2021 for help with their space. Little Safari’s multi-purpose room is used for play, music, reading, arts/crafts, meals, games etc….. lots of moving and laughing = lots of noise! According to the owner “The noise level is deafening at times to the point you can’t hear anything, just noise”

The fanciful mural on the playroom wall looks great, but when you look closer, that glossy painted surface reflects sound like glass! Luckily, Fireflex Pyramid foam can quiet that down!

Technical consultant Cameron Girard settled on a remediation package that included FireFlex Acoustic Pyramid Foam panels distributed throughout the ceiling of the multi-purpose room. Safe to say, they were very happy with the results!!

The checkerboard install of the foam helped to distribute the absorption over the loudest areas of the room.

From the owner…..“Cameron, Thank you for all of your help and expertise in sound suppression!!! I have had people tell me upon entering the front door “wow, it’s much quieter in here” Such a noticeable difference. You may have saved my hearing and sanity!!!”

DIY – Treating a Wall – BlockAid® and SoundChannels®

Posted by Acoustics First in Absorption, Animal Shelters, Auditorium, Broadcast Facilities, Classrooms, DIY, Fitness, Government, Gymnasium, Home Entertainment, Home Theater, HOW TO, Media Room, Multipurpose Rooms, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, School & Educational Facilities, Sound proofing, Studio Control Room, Teaching Rooms, Teleconferencing, Theater, Uncategorized, Vocal Booth, Voice Over on July 16, 2015

On many occasions, we get asked about common ways to treat a wall (or walls) either for broadcast, podcast, or other voice recording scenario – where they not only want to tame the reflections within the room, but also block a certain amount of sound coming into – or leaving the room.

On many occasions, we get asked about common ways to treat a wall (or walls) either for broadcast, podcast, or other voice recording scenario – where they not only want to tame the reflections within the room, but also block a certain amount of sound coming into – or leaving the room.

Budget is frequently an issue, major construction is usually unwanted, but effective results are always required.

We’re going to show you how to handle a room upgrade – cut down on the sound transmission and cut the room reflections – all with the same skills required to hang high quality wall coverings! Let’s see how you can cover a wall with BlockAid® vinyl sound barrier to block unwanted sound, then go back and cover that with an absorptive layer of Sound Channels® wall covering to finish it off!

This treatment is not recommended for renters, as this is not an easy upgrade to undo. However, if you have an extra bedroom you are using as Podcast studio, this is a great way to treat it… Let’s get started!

Installing BlockAid®

Good job! Now, take a breather while that dries, and notice how much less sound is passing through the walls. This is when you will notice that the sounds are now coming from under the door, and through the leaky old window. These can be taken care of in different ways…. but the easiest way is the same way you deal with keeping the cold out! Get some weather strip, a door skirt, seal the gaps around the frame of the door, and windows, maybe go out and buy some heavy curtains for the windows… if you have some leftover BlockAid®, you can always get some Industrial Velcro and temporarily stick a piece over the window!

Installing Sound Channels®

That’s it!

This treatment is a common first step in treating many professional broadcast studios – it gives you extra isolation with the barrier and takes the edge of the sound reflections. Many professional environments then go back and add some additional treatments such as bass traps, diffusers, and broadband absorber panels – especially if these studios are planning on bringing in any musical guests.

This isn’t just for home studios. It works great for kids play rooms, bedrooms, home theaters, home gyms, and any place you want to block sound and tame the sound inside the room.

Customize your space as you will, but this treatment is a consistent winner for cost and performance, and is a great way to get started without breaking the bank!

You must be logged in to post a comment.