Model D Patent Granted

Posted by Acoustics First in Uncategorized on November 24, 2015

Acoustics First® is pleased to announce that the Patent for our new Art Diffusor® Model D is now official!

www.radiomagonline.com/products/0002/acoustics-first…patent/37169

We thought we’d also share this recent piece from Robotics Tomorrow. Written by AFC’s Cameron Girard, this article shares some insights into the process of product development and prototyping.

http://www.roboticstomorrow.com/article/2015/11/3d-printing-and-acoustics-rapid-prototyping-of-sound-diffusers/7096

This latest addition to the Art Diffusor® series has already found use in a wide range of applications, from recording and broadcast to pro audio and home theater.

|

|

“They make a tremendous difference in the room, having effortlessly fixed a nasty flutter echo I was experiencing.” – Julian Evans, musician and sound engineer.

Silent Pictures® – Large and Small!

Posted by Acoustics First in Uncategorized on October 29, 2015

Here at Acoustics First® our clients are calling on us more than ever to assist with the challenge of providing materials that not only solve their acoustical issues, but also add an element of visual excitement.

We thought we’d share some pictures from two recent projects featuring our Silent Pictures® line of acoustical panels.

The first job was relatively straight forward. An Italian restaurant had us print a variety of black & white photos on their sound absorption panels.

Family History in Silent Pictures® |

The second job was more complex. It involved producing an array of large acoustic panels which collectively form the even larger mural pictured below. This required a great deal of precision, but the end results turned out fantastic!

As always, Acoustics First® is here to help with all of your sound control needs, no matter how large or small.

Custom Panels and the Aesthetics of Acoustics

Posted by Acoustics First in Absorption, Product Applications, Products, School & Educational Facilities on September 29, 2015

There is a saying in our industry: When it comes to designing a space, acoustic consultants are blind and architects are deaf. In reality, it is in both parties best interest to consider the other side when designing a space, so visual form meets acoustic functionality.

Let’s be real, standard acoustic treatment is far from sexy. Typical 2’x4’ panels, while fully functional, don’t present the architects with much in terms of visual interest. This is where Acoustics First can supplement the design goals of the architect/interior designer with our technical expertise to find a custom solution that sounds and looks great.

Hexagonal ToneTiles™ at Kramer Middle School.

Recently, Acoustics First® was asked to provide the custom panels for the cafeteria at Kramer Middle School in Washington DC. It was settled that hexagonal ToneTiles™ would be suspended as clouds in a geometric pattern around the ceiling. The resulting “honeycomb” effect is not only visually appealing, but the treatments effectively cut down the overall reverberation; increasing speech intelligibility and making the space more comfortable for a variety of activities.

Acoustics First® enjoys the inherent challenge in making these custom panels a success. We have plenty of experience in fulfilling the design goals of architects and interior designers. Interested in seeing more of these custom projects?

Visit http://acousticsfirst.com/installations-education-school-museum.htm to see some more examples.

Feel free to give Acoustics First® a call to discuss your custom treatment needs!

Rapid Prototyping – Designing the future… Now!

Posted by Acoustics First in Company Information, Diffusion, Press Release, Products, Video on August 31, 2015

As the summer of 2015 winds down, we here at Acoustics First thought we’d share our latest acquisition with our readers.

As the summer of 2015 winds down, we here at Acoustics First thought we’d share our latest acquisition with our readers.

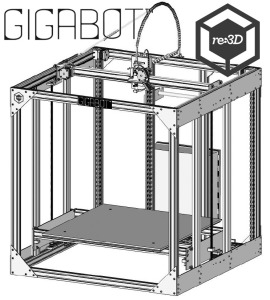

The GigaBot™ by re:3D. Or as we call it “The GiggleBot!”

Meet the Gigabot™

(or as we call him “Gigglebot”).

This amazing large format 3D printer was developed by re:3D, an outstanding company whose principals come from varied backgrounds which include experience working at NASA, among other things.

The eight cubic foot build volume of this beast makes it ideal for the rapid development and prototyping of our industry leading sound diffusers! We look forward to using this wonderful device on many projects in the years to come.

Watch this short video we made during one of our trial runs. For this calibration test we chose to print a scaled down version of our patented Model D Art Diffusor®.

Who said manufacturing was boring?!?!

- Acoustics First

DIY – Treating a Wall – BlockAid® and SoundChannels®

Posted by Acoustics First in Absorption, Animal Shelters, Auditorium, Broadcast Facilities, Classrooms, DIY, Fitness, Government, Gymnasium, Home Entertainment, Home Theater, HOW TO, Media Room, Multipurpose Rooms, Music Rehearsal Spaces, Music Tracking Room, Product Applications, Recording Facilities, Recording Studio, School & Educational Facilities, Sound proofing, Studio Control Room, Teaching Rooms, Teleconferencing, Theater, Uncategorized, Vocal Booth, Voice Over on July 16, 2015

On many occasions, we get asked about common ways to treat a wall (or walls) either for broadcast, podcast, or other voice recording scenario – where they not only want to tame the reflections within the room, but also block a certain amount of sound coming into – or leaving the room.

On many occasions, we get asked about common ways to treat a wall (or walls) either for broadcast, podcast, or other voice recording scenario – where they not only want to tame the reflections within the room, but also block a certain amount of sound coming into – or leaving the room.

Budget is frequently an issue, major construction is usually unwanted, but effective results are always required.

We’re going to show you how to handle a room upgrade – cut down on the sound transmission and cut the room reflections – all with the same skills required to hang high quality wall coverings! Let’s see how you can cover a wall with BlockAid® vinyl sound barrier to block unwanted sound, then go back and cover that with an absorptive layer of Sound Channels® wall covering to finish it off!

This treatment is not recommended for renters, as this is not an easy upgrade to undo. However, if you have an extra bedroom you are using as Podcast studio, this is a great way to treat it… Let’s get started!

Installing BlockAid®

Good job! Now, take a breather while that dries, and notice how much less sound is passing through the walls. This is when you will notice that the sounds are now coming from under the door, and through the leaky old window. These can be taken care of in different ways…. but the easiest way is the same way you deal with keeping the cold out! Get some weather strip, a door skirt, seal the gaps around the frame of the door, and windows, maybe go out and buy some heavy curtains for the windows… if you have some leftover BlockAid®, you can always get some Industrial Velcro and temporarily stick a piece over the window!

Installing Sound Channels®

That’s it!

This treatment is a common first step in treating many professional broadcast studios – it gives you extra isolation with the barrier and takes the edge of the sound reflections. Many professional environments then go back and add some additional treatments such as bass traps, diffusers, and broadband absorber panels – especially if these studios are planning on bringing in any musical guests.

This isn’t just for home studios. It works great for kids play rooms, bedrooms, home theaters, home gyms, and any place you want to block sound and tame the sound inside the room.

Customize your space as you will, but this treatment is a consistent winner for cost and performance, and is a great way to get started without breaking the bank!

You must be logged in to post a comment.